SMT walda dalilai

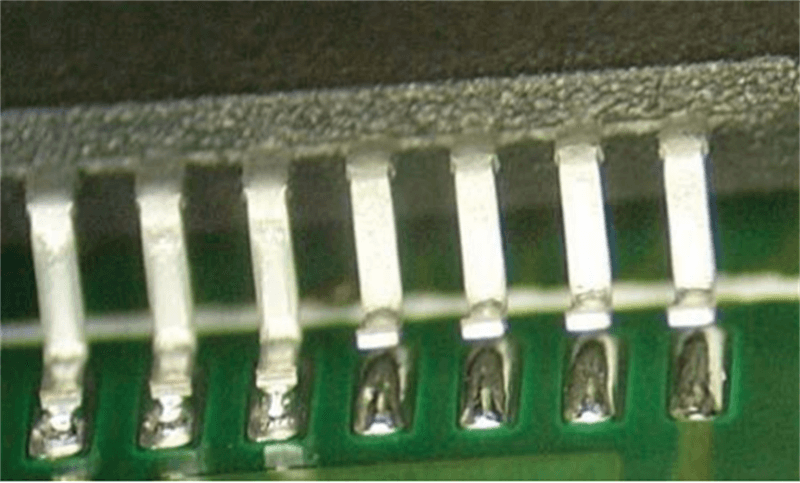

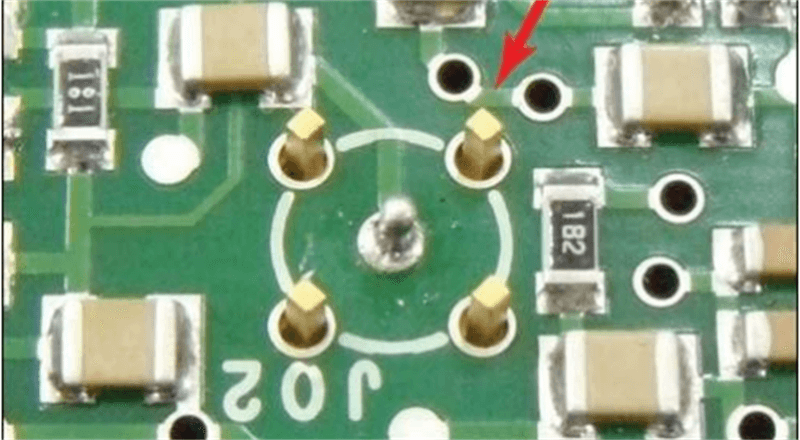

1. PCB kushin zane lahani

A cikin tsarin zane na wasu PCB, saboda sarari yana da ƙananan ƙananan, ramin za a iya buga shi kawai a kan kushin, amma manna mai solder yana da ruwa, wanda zai iya shiga cikin ramin, wanda ya haifar da rashi mai solder a cikin walda reflow. don haka lokacin da fil ɗin ya gaza cin tin, zai haifar da walƙiya ta zahiri.

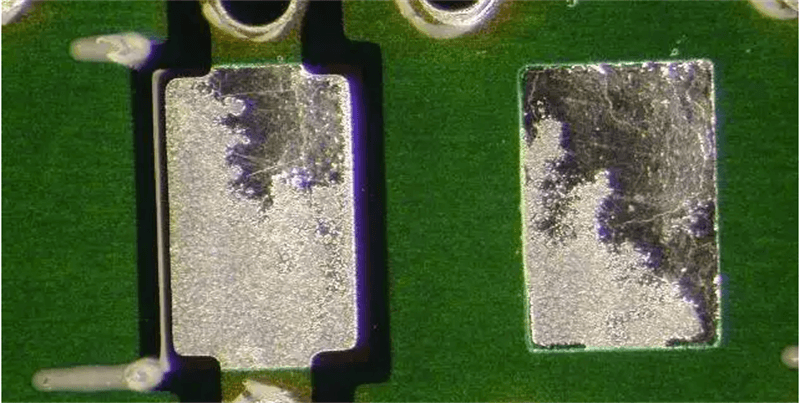

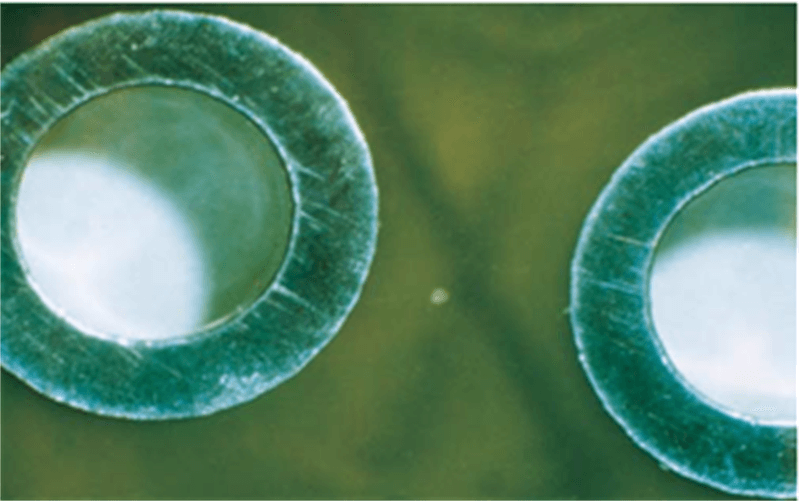

2.Pad surface hadawan abu da iskar shaka

Bayan sake tinning oxidized pad, reflow waldi zai kai ga kama-da-wane waldi, don haka lokacin da kushin oxidizes, shi yana bukatar a bushe da farko.Idan oxidation yana da tsanani, yana buƙatar a watsar da shi.

3.Reflow zafin jiki ko babban zafin jiki yankin lokaci bai isa ba

Bayan an gama facin, zafin jiki bai isa ba lokacin wucewa ta yankin preheating na reflow da kuma yawan zafin jiki na yau da kullun, wanda ke haifar da wani zafi mai zafi wanda bai faru ba bayan shigar da babban yankin reflow, wanda ke haifar da rashin isasshen cin abinci. na bangaren fil, haifar da kama-da-wane waldi.

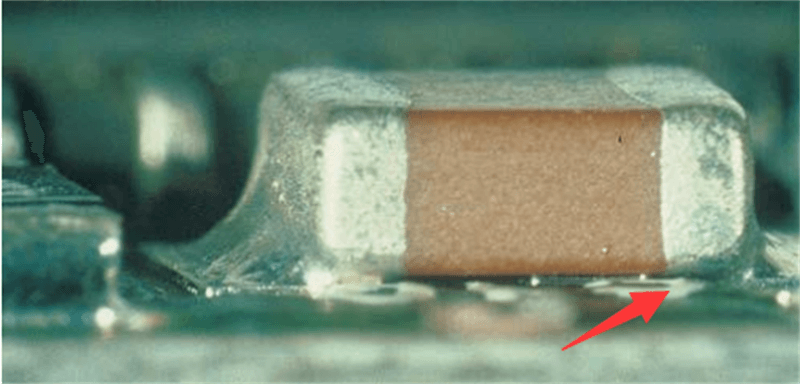

4.Solder manna bugu ne m

A lokacin da solder manna da aka goga, yana iya zama saboda kananan budewa a cikin karfe raga da kuma wuce kima matsa lamba na bugu scraper, haifar da m solder manna bugu da sauri volatilization na solder manna ga reflow waldi, sakamakon kama-da-wane waldi.

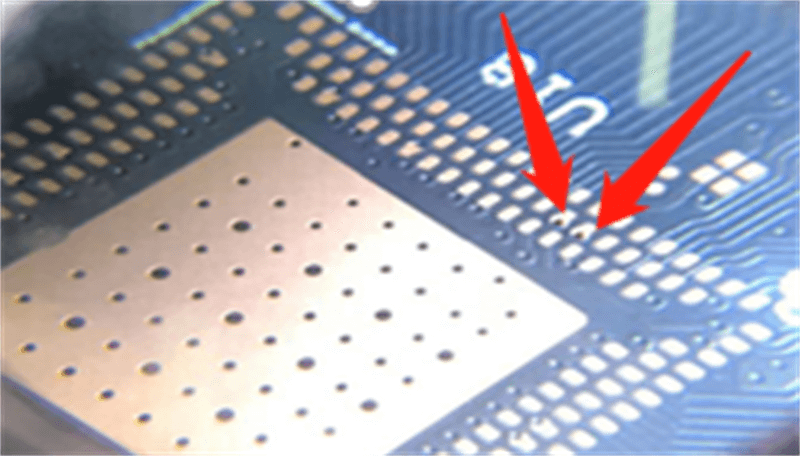

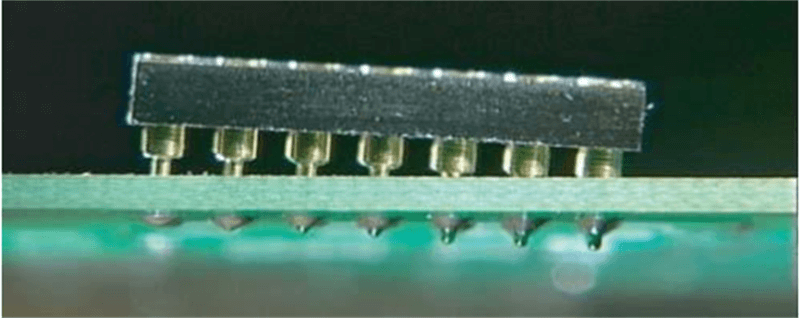

5.High-pin na'urorin

Lokacin da babban-pin na'urar ne SMT, yana iya zama cewa saboda wasu dalilai, bangaren ya lalace, PCB allon yana lankwasa, ko kuma mummunan matsin lamba na injin sanyawa bai isa ba, yana haifar da narkewar zafi daban-daban na solder, wanda ya haifar da kama-da-wane waldi.

DIP kama-da-wane waldi dalilai

1.PCB toshe-in rami zane lahani

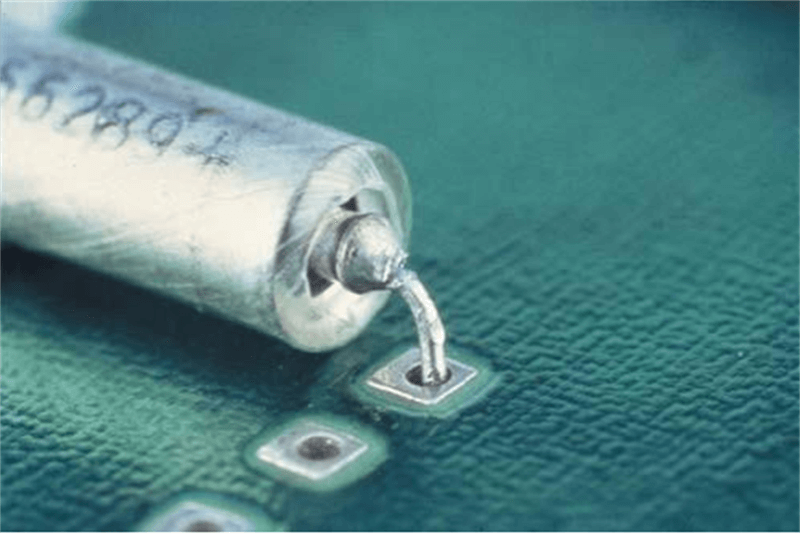

PCB plug-in rami, haƙuri tsakanin ± 0.075mm, PCB marufi rami ya fi girma fiye da fil na jiki na'urar, da na'urar za a sako-sako da, sakamakon rashin isasshen tin, kama-da-wane waldi ko iska waldi da sauran ingancin matsaloli.

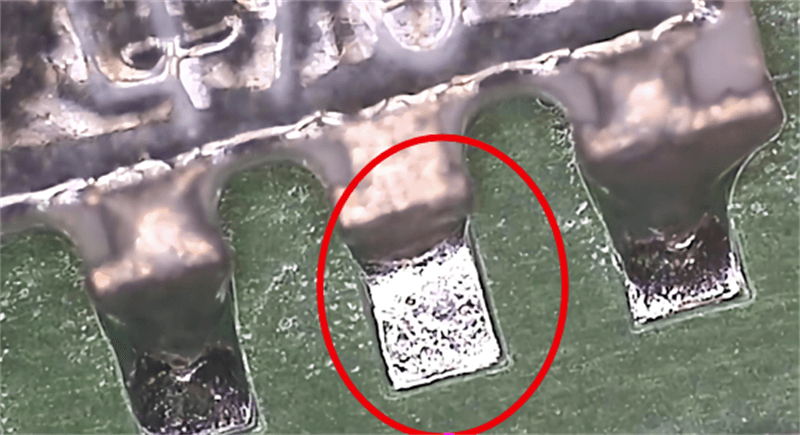

2.Pad da rami oxidation

Ramin kushin PCB ba su da tsabta, oxidized, ko gurɓata da kayan sata, maiko, gumi, da dai sauransu, wanda zai haifar da rashin walƙiya mara kyau ko ma rashin walƙiya, yana haifar da walda mai kama da walda ta iska.

3.PCB jirgi da abubuwan ingancin na'urar

Allolin PCB da aka siya, abubuwan da aka gyara da sauran abubuwan siyarwa ba su cancanta ba, ba a gudanar da gwajin karbuwa sosai ba, kuma akwai matsaloli masu inganci kamar walda mai kama da juna yayin taro.

4.PCB allon da na'urar sun ƙare

Allon PCB da aka siya, saboda lokacin ƙirƙira ya yi tsayi da yawa, yanayin wurin ajiyar ya shafa, kamar zafin jiki, zafi ko iskar iskar gas, yana haifar da abubuwan al'ajabi kamar walda mai kama-da-wane.

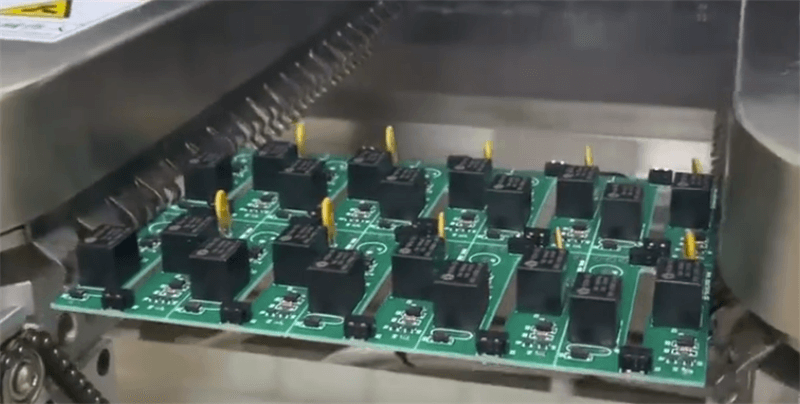

5.Wave soldering kayan dalilai

A high zafin jiki a cikin kalaman waldi tanderu take kaiwa zuwa kara hadawan abu da iskar shaka abu na solder abu da kuma saman da tushe abu, sakamakon rage mannewa da surface zuwa ruwa solder abu.Bugu da ƙari, babban zafin jiki kuma yana lalata ƙasa mai ƙaƙƙarfan kayan tushe, yana haifar da raguwar aikin capillary da ƙarancin ɗimbin yawa, yana haifar da walda mai kama-da-wane.

Lokacin aikawa: Jul-11-2023