[Kayan busassun] SMT facin yankan rarrabuwar kwano a cikin sarrafawa, nawa kuka sani?(2023 Essence), kun cancanci shi!

Yawancin nau'ikan kayan samarwa ana amfani da su a sarrafa facin SMT.Tinnote shine mafi mahimmanci.Ingancin facin kwano zai shafi ingancin walda kai tsaye na sarrafa facin SMT.Zabi nau'ikan tinnuts daban-daban.Bari in gabatar da rabe-raben da ake yi na gama-gari:

Weld manna wani nau'i ne na ɓangaren litattafan almara don haɗa foda mai walda tare da manna mai kama da walda (rosin, diluent, stabilizer, da dai sauransu) tare da aikin welded.Dangane da nauyin nauyi, 80 ~ 90% sune ƙarfe gami.Dangane da girma, ƙarfe da solder sun kai kashi 50%.

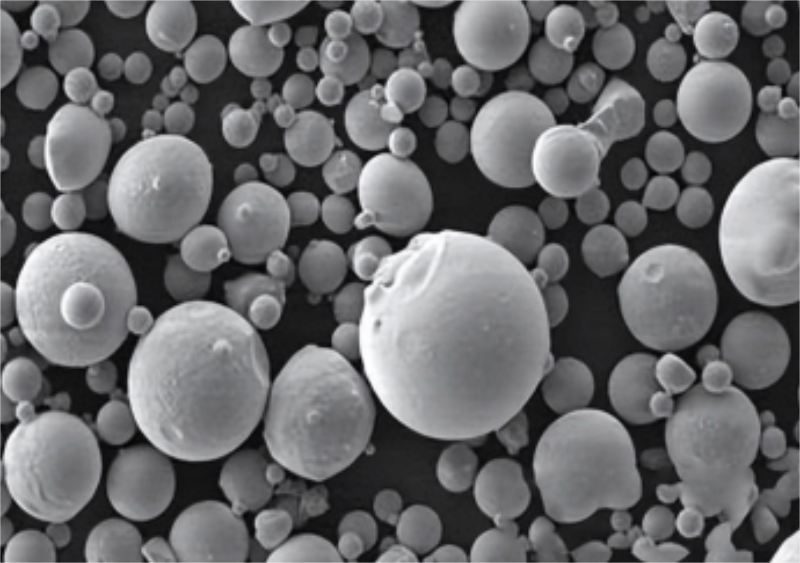

Hoto 3 Manna granules goma (SEM) (hagu)

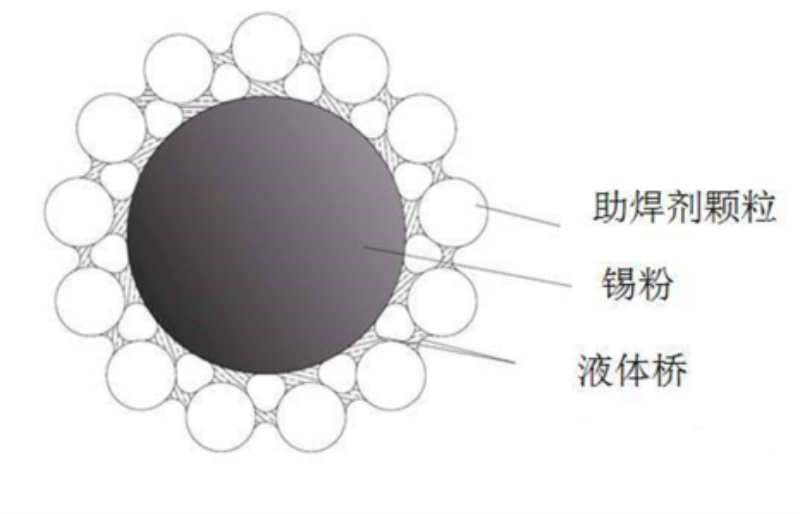

Hoto 4 Takamaiman zane na murfin foda (dama)

The solder manna ne m da gwangwani foda barbashi.Yana ba da mafi dacewa da ɓacin rai da zafi don haɓaka watsa zafi zuwa yankin SMT da rage tashin hankali na ruwa akan walda.Abubuwa daban-daban suna nuna ayyuka daban-daban:

① Mai narkewa:

Abubuwan da ke da ƙarfi na wannan kayan aikin walda yana da daidaitaccen daidaitawa na daidaitawa ta atomatik a cikin tsarin aiki na kwano, wanda ke da tasiri mafi girma ga rayuwar kullun walda.

② Gudun:

Yana taka muhimmiyar rawa wajen ƙara mannewar tin manna da gyara da hana PCB daga sake-oxidation bayan walda.Wannan sinadari na asali yana da muhimmiyar rawa wajen gyaran sassa.

③ Mai aiki:

Yana taka rawa na cire oxidized abubuwa na PCB jan karfe film surface Layer da kuma part SMT faci site, kuma yana da tasiri na rage surface tashin hankali na tin da gubar ruwa.

④ Tentacle:

Daidaita atomatik na danko na walƙiya na walda yana taka muhimmiyar rawa wajen bugawa don hana wutsiya da mannewa.

Na farko, bisa ga abun da ke ciki na solder manna rarrabuwa

1, lemar solder manna: ya ƙunshi abubuwan dalma, mafi girman cutarwa ga muhalli da jikin ɗan adam, amma tasirin walda yana da kyau, kuma farashin yana da ƙasa, ana iya amfani da shi ga wasu samfuran lantarki ba tare da buƙatun kare muhalli ba.

2, Gubar-free solder manna: muhalli m sinadaran, kadan cutarwa, amfani da muhalli m kayayyakin lantarki, tare da inganta na kasa muhalli bukatun, gubar-free fasahar a cikin smt sarrafa masana'antu zai zama Trend.

Na biyu, bisa ga narkewa batu na solder manna rarrabuwa

Gabaɗaya magana, ana iya raba wurin narkewar manna mai siyar zuwa babban zafin jiki, matsakaicin zafin jiki da ƙananan zafin jiki.

Babban zafin da aka saba amfani dashi shine Sn-Ag-Cu 305,0307;An samo Sn-Bi-Ag a cikin matsakaicin zafin jiki.Ana amfani da Sn-Bi a ƙananan zafin jiki.A cikin SMT faci ana buƙatar zaɓar aiki bisa ga halaye daban-daban na samfur.

Uku, bisa ga fineness na tin foda rabo

Dangane da diamita na tin foda, za a iya raba man dana zuwa 1, 2, 3, 4, 5, 6 na foda, wanda 3, 4, 5 foda shine mafi yawan amfani.Mafi nagartaccen samfurin, zaɓin foda na gwangwani yana buƙatar ƙarami, amma ƙarami foda foda, daidaitaccen yankin oxidation na tin foda zai ƙaru, kuma foda mai zagaye yana taimakawa wajen haɓaka ingancin bugawa.

No. 3 foda: Farashin yana da arha, wanda aka saba amfani dashi a cikin manyan hanyoyin smt;

No. 4 foda: fiye da amfani da m kafar IC, smt guntu aiki;

No. 5 foda: Sau da yawa ana amfani da su a cikin ainihin abubuwan walda, wayoyin hannu, allunan da sauran samfuran buƙatu;Mafi wahala samfurin sarrafa facin smt shine, mafi mahimmancin zaɓi na manna mai siyar shine, kuma zaɓin manna mai dacewa don samfurin yana taimakawa haɓaka tsarin sarrafa facin smt.