Ƙimar Hukumar Gudanarwa & PCB Majalisar & Sabis na Majalisar Lantarki & Kamfanin kera kayan lantarki - XinDaChang Co., Limited

Kamar yadda manyan daya tasha PCB Majalisar sabis naka a kasar Sin, A XinDaChang yayi high quality, kudin tasiri da kuma bayyana PCB hukumar kayayyakin da kuma samar da PCB masana'antu, Electronics taro masana'antu, aka gyara tushen, Akwatin gina taro da PCBA gwajin sabis ga abokan ciniki.

Don cikakken taron hukumar kewayawa, muna kula da tsarin gabaɗayan, gami da ƙirƙira Ƙirƙirar Allolin da'ira, abubuwan da aka haɗa, bin diddigin oda, ci gaba da saka idanu akan inganci da taron kwamitin PCB na ƙarshe. Ganin cewa maɓalli na juzu'i, abokin ciniki na iya samar da PCBs da wasu abubuwan haɗin gwiwa, sauran sassan kuma mu za a sarrafa su.

Menene PCB taro

Ana kiran allon da'ira da ke gaban taro na kayan lantarki da ake kira Printed Circuit Board. Bayan sayar da duk abubuwan da ke kan allo, an san shi da Printed Circuit Board Assembled, mun kiraPCB taro. Cikakkar tsarin taron abubuwan da ake kira Printed Circuit Assembly ko Printed Circuit Board Assembly ko PCB board meeting. A cikin wannan tsari, ana amfani da kayan aikin haɗin kai daban-daban na atomatik da na hannu. Mu ne masu tarawa waɗanda ke ba da taron PCB.

Tambayoyi don XinDaChang - Ayyukan Taro na PCB

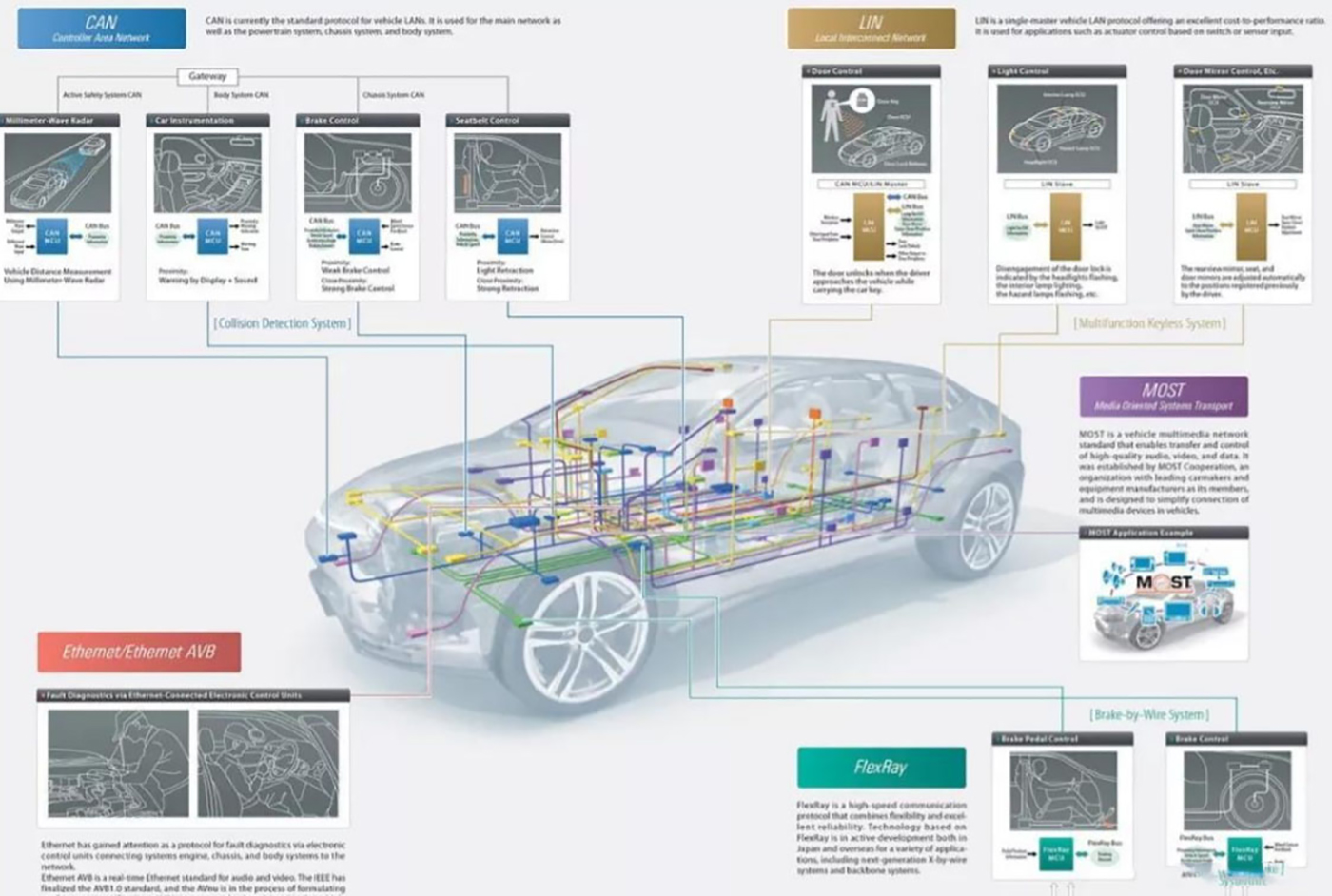

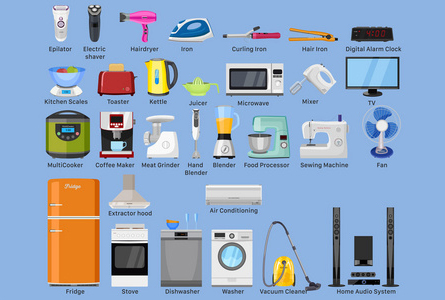

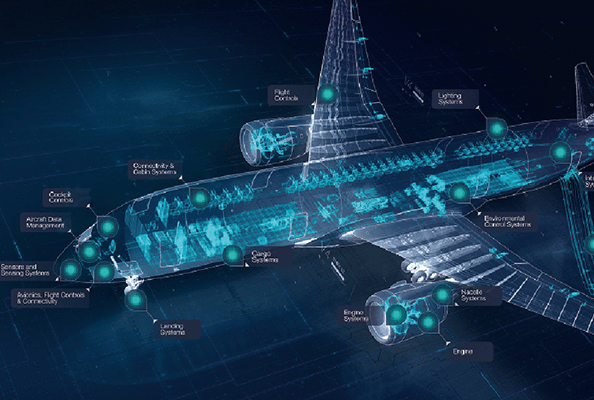

HiTech Circuits ya ƙware wajen samar da cikakkiyar sabis ɗin taro na Hukumar da'ira (PCB). Wannan ya haɗa da fasahar hawan dutse (SMT), haɗin fasaha ta hanyar-rami (THT), haɗuwa-fasaha mai gauraya, taron samfuri, samar da ƙananan ƙararrawa, da kuma mafita na turnkey. An ƙera sabis ɗinmu don ɗaukar nau'ikan masana'antu daban-daban, gami da amma ba'a iyakance ga sadarwa ba, na'urorin likitanci, motoci, da na'urorin lantarki masu amfani.

Ee, muna ba da cikakkiyar sabis na taro na PCB. Wannan yana nufin za mu iya sarrafa kowane mataki na aikin ku daga abubuwan da aka samo asali, ƙirƙira PCB, taro, gwaji, da jigilar kaya na ƙarshe. Maganin mu na turnkey an ƙirƙira shi don adana lokaci da rage wahalar daidaitawa tare da masu kaya da yawa.

Lallai! Muna sanye da fasahar masana'antu na ci gaba kuma muna da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun tarurrukan PCB. Ko aikinku ya ƙunshi manyan haɗin kai (HDI), kayan aikin faranti masu kyau, ko buƙatar dabarun siyarwa na musamman, muna da ƙwarewa da albarkatu don biyan bukatunku.

Muna amfani da ƙaƙƙarfan tsari na tabbatarwa wanda ya haɗa da dubawar gani mai sarrafa kansa (AOI), duban X-ray, gwajin kewayawa (ICT), da gwajin aiki don ganowa da gyara kowane lahani ko matsala. Ana aiwatar da matakan sarrafa ingancin mu a kowane mataki na tsarin taro don tabbatar da cewa kowane taron PCB ya cika manyan ka'idodin mu da takamaiman buƙatun ku.

HiTech Circuits ya himmatu don isar da samfuran inganci. An ba mu takaddun shaida a ƙarƙashin ISO 9001 don tsarin sarrafa ingancin mu, tabbatar da cewa ayyukanmu da samfuranmu sun cika ƙa'idodin ƙasa da ƙasa don inganci da aminci.

Don cikakkun bayanai da cikakkun bayanai, da fatan za a samar mana da fayilolin ƙirar PCB ɗinku (Faylolin Gerber, BOM (Bill of Materials), zanen taro, da kowane takamaiman umarni ko buƙatun da kuke da shi. Bugu da ƙari, cikakkun bayanai game da yawa da tsarin lokaci don aikinku zai taimaka mana samar muku da ingantaccen kimantawa.

Ee, samfurin PCB taro ɗaya ne daga cikin mahimman ayyukan mu. Prototyping yana ba ku damar gwadawa da kuma daidaita ƙirar ku kafin motsawa zuwa samarwa da yawa. Muna ba da lokutan juyowa da sauri don samfura don taimakawa haɓaka zagayowar ci gaban ku.

Muna nufin samar da ƙididdiga da sauri da sauri. Yawanci, kuna iya tsammanin samun cikakken bayani a cikin sa'o'i 24 zuwa 48 bayan ƙaddamar da duk takaddun da suka dace da bayanai game da aikin ku.

Ee, mun fahimci mahimmancin haɗuwa da ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun bayanai ke bayarwa kuma za mu iya ɗaukar umarni na taron PCB na gaggawa. Da fatan za a tuntuɓe mu tare da takamaiman buƙatunku, kuma za mu yi iya ƙoƙarinmu don saduwa da tsarin lokacinku ba tare da lalata inganci ba.

Mun yi imani da sanar da abokan cinikinmu kowane mataki na hanya. Da zarar an ba da odar ku, za a ba ku mai sarrafa ayyukan da zai zama wurin tuntuɓarku. Kuna iya tsammanin sabuntawa akai-akai kan matsayin odar ku kuma koyaushe ana maraba da tuntuɓar manajan aikin ku don kowace tambaya ko sabuntawa.

Fasahar mu

A XinDaChang, muna amfani da sabbin ci gaba a fasaha don taron hukumar da'ira da aka buga. Wasu daga cikin fasaha da injina da muke amfani da su sun haɗa da:

• Injin siyar da igiyar ruwa

• Zaba da wuri

• AOI & X-ray

• Rufewa mai sarrafa kansa

• Injin SPI

Surface Mount Technology Assembly (SMT Majalisar)

A XinDaChang, muna da damar yin amfani da fasahar hawan dutse don haɗa PCBs ɗinku, ta amfani da na'urar ɗaukar hoto da wuri. Muna amfani da fasahar haɗuwa ta ƙasa kamar yadda ya fi dacewa da tsada kuma abin dogaro fiye da sauran hanyoyin haɗin PCB na gargajiya. Misali, tare da taron SMT ana iya haɗa ƙarin kayan lantarki a cikin ƙaramin sarari akan PCB. Wannan yana nufin ana iya keɓance PCBs cikin sauƙi da inganci, kuma a ƙarar mafi girma.

Gwaji da sarrafa inganci

Don tabbatar da tsarin taro na PCB ba shi da laifi, muna amfani da sabbin gwajin AOI da X-Ray da dubawa. AOI, ko dubawar gani ta atomatik, gwada PCBs don gazawar bala'i da lahani masu inganci ta hanyar bincika su kai tsaye tare da kyamara. Muna amfani da gwaji mai sarrafa kansa a matakai da yawa na tsarin taron mu na PCB don tabbatar da duk PCB ɗinmu na mafi inganci.

Sabis ɗin Taro Mai Sauƙi na PCB

Ayyukan taron mu na PCB sun wuce sama da abin da matsakaicin PCB taron kamfanin zai yi. Muna ba da sabis daban-daban na madaidaicin sabis na taron hukumar da'ira don matakai daban-daban na haɓaka samfuran ku, gami da:

• Samfurin PCB Majalisar: Dubi yadda ƙirar PCB ɗin ku ke aiki kafin samar da babban tsari. Nau'in samfurin mu na PCB yana ba mu damar isar da samfuri mai sauri, don haka zaku iya gano duk wani ƙalubale mai yuwuwa a cikin ƙirar ku cikin sauri da haɓaka ingancin allunan ku na ƙarshe.

• Ƙarƙashin Ƙarfafa, Babban Haɗin PCB: Idan kuna buƙatar adadin alluna daban-daban don aikace-aikace na musamman, HitechPCB shine kamfanin ku.

• Babban-Volume PCB Majalisar: Mu ne daidai a matsayin gwani a cranking fitar da manyan PCB taro umarni kamar yadda muke a isar kananan.

• Majalisar PCB da aka keɓe & Bangaren PCB: Ayyukan taronmu na PCB ɗinmu sun haɗu da IPC Class 2 ko IPC ajin 3, suna ISO 9001: 2015-certified kuma sun dace da RoHS.

• Cikakken Turnkey PCB Assembly: Hakanan ISO 9001: 2015-certified da RoHS-compliant, mu turnkey PCB taro damar mu mu kula da dukan aikin daga farko zuwa gama, don haka za ka iya shiga da kuma fara cin gajiyar ƙãre samfurin nan da nan.

Daga SMD zuwa ramuka da gauraye ayyukan PCB, muna yin su duka, gami da bincike na Valor DFM/DFA kyauta da gwajin aiki don tabbatar da ingancin allunan ku, ba tare da ƙaramin buƙatun farashi ko ƙarin cajin kayan aiki ba lokacin da kuka sake yin oda.

XinDaChang ya haɗu da ingantattun ƙwararrun tsarin ISO da sabbin fasahohin taro da marufi don sadar da samfuran lantarki masu jagorancin kasuwa. Daga taron samfur ta hanyar shinge zuwa gwaji da tattarawa, layin Hitech's SMT suna amfani da ingantattun fasahohi a cikin masana'antar gami da:

Saurin jujjuya pcb taron Flip Chip Technologies

0201 Fasaha

Fasahar Solder Kyautar Gubar

Madadin PCB ya ƙare

Shigar mai kaya na farko

Ƙira da tallafin injiniya

PCB masana'antu da PCB taro

Taro na baya

Ƙwaƙwalwar ƙwaƙwalwa da na'urorin gani

Kebul da taron kayan aiki

Filastik allura gyare-gyare

Daidaitaccen machining

Makarantu

Haɗuwa da hardware da software

Ayyukan BTO da CTO daidai da bukatun ku

Gwajin dogaro

Lean da shida Sigma ingancin tafiyar matakai

Menene bambanci tsakanin Buga da'ira da PCB Majalisar?

PCB ita ce allon da'ira da aka buga saboda ana yin ta ta hanyar bugu na lantarki, don haka ana kiranta da allo mai “bugu”. PCB wani muhimmin bangaren lantarki ne a cikin masana'antar lantarki, tushe ne na lantarki. Yana da goyon bayan kayan aikin lantarki da kuma mai ɗaukar haɗin lantarki na kayan lantarki. PCB da aka yadu amfani wajen samar da lantarki kayayyakin.

Majalisar PCB gabaɗaya tana nufin kwararar sarrafawa, wanda kuma za'a iya fahimtarsa azaman allon da'ira da aka gama, wato, PCBA za'a iya ƙidaya kawai bayan an kammala ayyukan akan PCB. PCB yana nufin komai na allon da'ira buga wanda babu sassa akansa. Abin da ke sama shine bambanci tsakanin PCB da PCBA.

SMT (fasahar da aka ɗora saman sama) da DIP (Dual In-line Package) duka hanyoyi ne don haɗa sassa akan allon kewayawa. Babban bambanci shine SMT baya buƙatar ramuka akan PCB, amma a cikin tsomawa, yana buƙatar saka fil a cikin rami da aka haƙa.

SMT galibi yana amfani da injin hawa don hawa wasu ƙananan sassa da ƙananan sassa akan allon kewayawa. Its samar tsari ne PCB sakawa, solder manna bugu, hawa da hawa inji, reflow tanda, da dubawa.

Tsoma "toshe-in", wato saka sassa akan allon PCB. Wani nau'i ne na haɗakar da plug-in lokacin da wasu sassa suke da girma kuma basu dace da fasaha na hawa ba. Babban tsarin samar da shi shine manne baya, toshewa, dubawa, sayar da igiyar ruwa, goge farantin, da kuma kammala dubawa.