Idan aka kwatanta da na'ura mai ba da wutar lantarki na tushen silicon, SiC (silicon carbide) semiconductor na wutar lantarki yana da fa'ida mai mahimmanci a cikin sauyawa mita, asara, zubar da zafi, miniaturization, da dai sauransu.

Tare da babban sikelin samar da silicon carbide inverters ta Tesla, ƙarin kamfanoni kuma sun fara ƙaddamar da samfuran silicon carbide.

SiC yana da "ban mamaki", ta yaya aka yi shi a duniya? Menene aikace-aikacen yanzu? Mu gani!

01 ☆ Haihuwar SiC

Kamar sauran masu sarrafa wutar lantarki, sarkar masana'antar SiC-MOSFET ta haɗa dada dogon crystal - substrate - epitaxy - zane - masana'antu - marufi mahada.

Dogon crystal

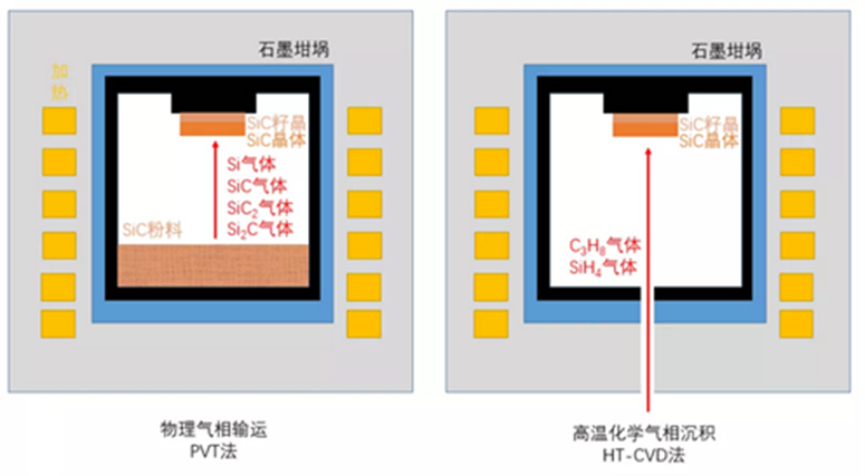

A lokacin dogon crystal mahada, sabanin shirye-shiryen da Tira Hanyar amfani da guda crystal silicon, silicon carbide yafi rungumi dabi'ar iskar gas Hanyar (PVT, kuma aka sani da ingantaccen Lly ko iri crystal sublimation Hanyar), high zafin jiki sinadaran gas ajiya Hanyar ( HTCVD) kari.

☆ Core mataki

1. Carbonic m albarkatun kasa;

2. Bayan dumama, carbide m ya zama gas;

3. Gudun iskar gas zuwa saman kristal iri;

4. Gas yana tsiro a saman kristal iri ya zama crystal.

Madogararsa na hoto: “Batun Fasaha don wargaza ci gaban PVT silicon carbide”

Sana'a daban-daban sun haifar da manyan hasashe guda biyu idan aka kwatanta da tushen silicon:

Na farko, samarwa yana da wahala kuma yawan amfanin ƙasa ya ragu.Zazzabi na lokacin gas na tushen carbon yana girma sama da 2300 ° C kuma matsa lamba shine 350MPa. Duk akwatin duhu ana aiwatar da shi, kuma yana da sauƙin haɗuwa cikin ƙazanta. Yawan amfanin ƙasa ya fi tushe na silicon. Mafi girma diamita, ƙananan yawan amfanin ƙasa.

Na biyu shine jinkirin girma.Gudanar da tsarin PVT yana da hankali sosai, saurin yana kusan 0.3-0.5mm / h, kuma yana iya girma 2cm a cikin kwanaki 7. Matsakaicin zai iya girma kawai 3-5cm, kuma diamita na ingot crystal shine mafi yawa inci 4 da inci 6.

Silicon na tushen 72H na iya girma zuwa tsayin 2-3m, tare da diamita galibi inci 6 da 8-inch sabon ƙarfin samarwa don inci 12.Saboda haka, silicon carbide sau da yawa ana kiransa crystal ingot, kuma silicon ya zama crystal sanda.

Carbide silicon crystal ingots

Substrate

Bayan da dogon crystal aka kammala, shi shiga cikin samar da tsarin na substrate.

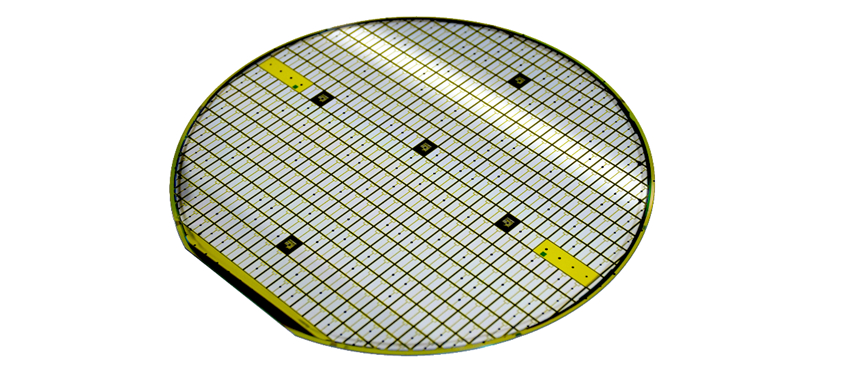

Bayan yankan da aka yi niyya, niƙa (m niƙa mai kyau), polishing (polishing mechanical), ultra-precision polishing (sinadarin aikin injiniya), ana samun substrate silicon carbide.

The substrate yafi takarawar da goyon bayan jiki, thermal conductivity da conductivity.Wahalhalun sarrafawa shine cewa silicon carbide abu yana da girma, kintsattse, kuma barga a cikin sinadarai. Don haka, hanyoyin sarrafa siliki na gargajiya na gargajiya ba su dace da siliki carbide substrate ba.

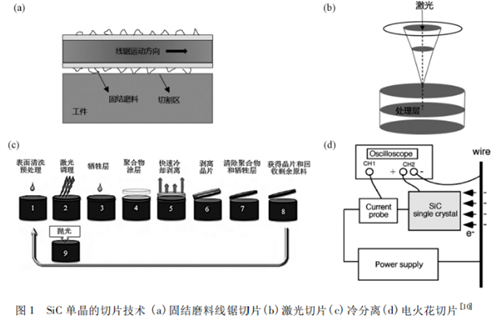

Ingancin tasirin yanke kai tsaye yana shafar aiki da ingantaccen amfani (farashi) samfuran siliki carbide, don haka ana buƙatar ƙarami, kauri iri ɗaya, da ƙarancin yankewa.

A halin yanzu,4-inch da 6-inch galibi suna amfani da kayan yankan layu da yawa,yankan lu'ulu'u na silicon cikin yanka na bakin ciki tare da kauri wanda bai wuce 1mm ba.

Jadawalin yankan layu da yawa

A nan gaba, tare da karuwar girman carbonized silicon wafers, karuwar buƙatun amfani da kayan aiki zai karu, kuma za a yi amfani da fasaha irin su slicing Laser da kuma rabuwar sanyi a hankali.

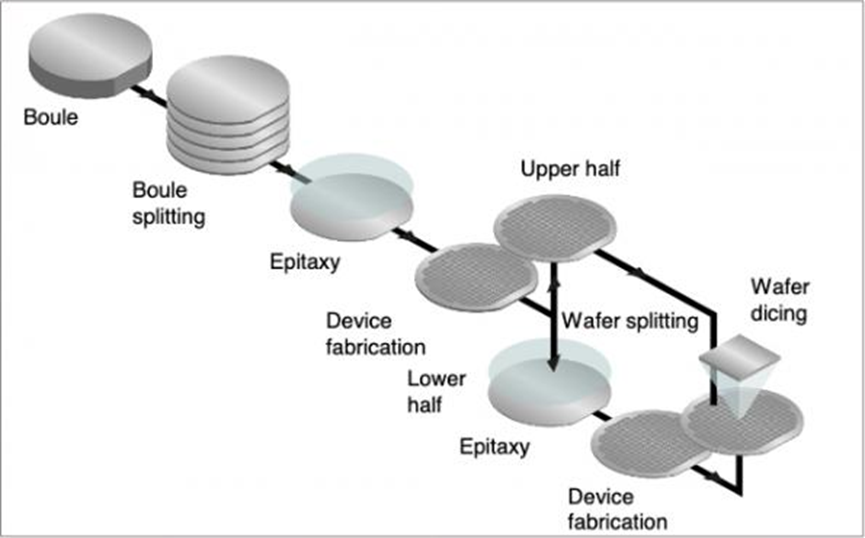

A cikin 2018, Infineon ya sami Siltectra GmbH, wanda ya haɓaka wani sabon tsari wanda aka sani da fashewar sanyi.

Idan aka kwatanta da na al'ada Multi-waya tsarin yankan tsarin asarar 1/4,tsarin fashewar sanyi kawai ya rasa 1/8 na siliki carbide abu.

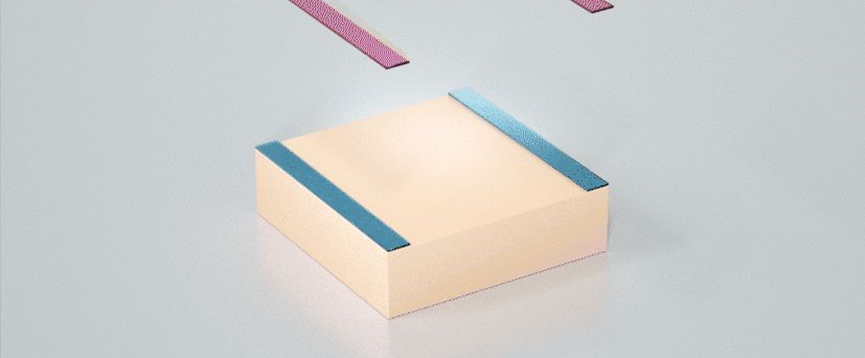

Tsawaitawa

Tun da silicon carbide abu ba zai iya yin ikon na'urorin kai tsaye a kan substrate, daban-daban na'urorin ake bukata a kan tsawo Layer.

Sabili da haka, bayan an gama samar da kayan aikin, ana yin wani takamaiman fim ɗin kristal guda ɗaya a kan ma'aunin ta hanyar haɓakawa.

A halin yanzu, ana amfani da mafi yawan hanyar shigar da iskar gas (CVD).

Zane

Bayan an yi substrate, ya shiga matakin ƙirar samfurin.

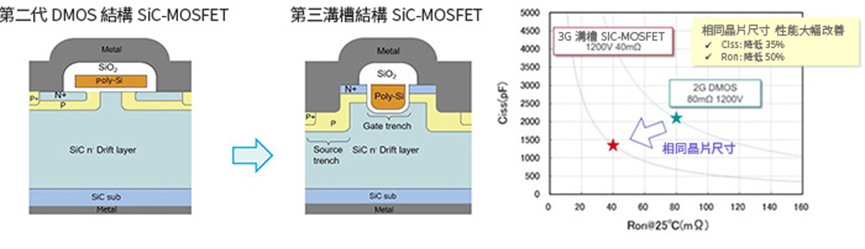

Ga MOSFET, abin da aka mayar da hankali kan tsarin ƙira shine ƙirar tsagi,a gefe guda don guje wa cin zarafin haƙƙin mallaka(Infineon, Rohm, ST, da dai sauransu, suna da shimfidar patent), kuma a daya bangaren zuwasaduwa da masana'anta da farashin masana'antu.

Ƙirƙirar wafer

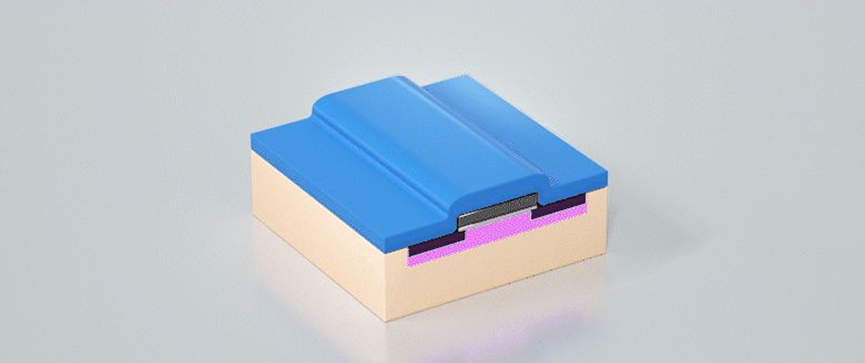

Bayan an gama ƙirar samfurin, ya shiga matakin masana'antar wafer,kuma tsarin ya yi kama da na silicon, wanda galibi yana da matakai 5 masu zuwa.

☆ Mataki na 1: Allurar abin rufe fuska

An yi fim ɗin fim ɗin silicon oxide (SiO2), an rufe hoton hoto, ƙirar photoresist an kafa ta hanyar matakan homogenization, fallasa, haɓakawa, da dai sauransu, kuma an canza adadi zuwa fim ɗin oxide ta hanyar etching.

☆ Mataki na 2: Ion implantation

Ana sanya wafer silicon carbide mai rufe fuska a cikin injin ion, inda ake allurar ions aluminium don samar da yankin doping na nau'in P, kuma anneal don kunna ion aluminum da aka dasa.

An cire fim din oxide, ana allurar ions nitrogen a cikin wani yanki na musamman na yankin P-type doping don samar da yanki mai sarrafa nau'in N na magudanar ruwa da tushen, kuma ana sanya ions nitrogen da aka dasa don kunna su.

☆ Mataki na 3: Yi grid

Yi grid. A cikin yankin da ke tsakanin tushen da magudanar ruwa, ana shirya Layer oxide Layer ta hanyar tsarin iskar oxygen mai girma, kuma ana ajiye layin lantarki na ƙofar don samar da tsarin sarrafa ƙofar.

☆Mataki na 4: Yin yadudduka na wucewa

An yi Layer Passivation. Ajiye Layer passivation tare da kyawawan halayen rufewa don hana rushewar interelectrode.

☆ Mataki na 5: Yi na'urorin lantarki masu magudanar ruwa

Yi magudanar ruwa da tushe. Wurin wucewa yana ratsawa kuma ana tofa karfe don samar da magudanar ruwa da tushe.

Tushen Hoto: Babban Birnin Xinxi

Ko da yake akwai ɗan bambanci tsakanin matakin tsari da tushen silicon, saboda halayen silicon carbide kayan,ion implantation da annealing bukatar a yi a cikin wani babban yanayin zafi(har zuwa 1600 ° C), babban zafin jiki zai shafi tsarin lattice na kayan da kansa, kuma wahalar kuma zai shafi yawan amfanin ƙasa.

Bugu da kari, don abubuwan MOSFET,ingancin iskar oxygen ta ƙofar kai tsaye yana rinjayar tashar motsi da amincin ƙofar, saboda akwai nau'ikan siliki da carbon atom a cikin kayan siliki carbide.

Sabili da haka, ana buƙatar hanyar haɓaka matsakaiciyar ƙofar kofa ta musamman (wani ma'ana ita ce takardar siliki carbide ta bayyana a sarari, kuma daidaitawar matsayi a matakin photolithography yana da wahala ga silicon).

Bayan an gama masana'antar wafer, ana yanke guntu ɗaya cikin guntu maras tushe kuma ana iya tattara su bisa ga manufar. Tsarin gama gari don na'urori masu hankali shine TO kunshin.

650V CoolSiC™ MOSFETs a cikin kunshin TO-247

Hoto: Infineon

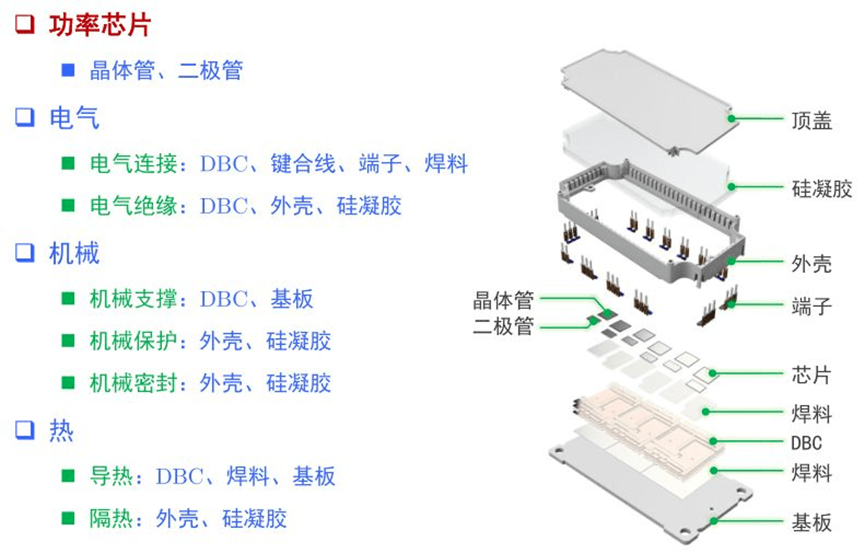

Filin mota yana da babban iko da buƙatun watsar zafi, kuma wani lokacin ya zama dole a gina hanyoyin gada kai tsaye (rabin gada ko gada cikakke, ko kuma an haɗa shi da diodes kai tsaye).

Don haka, galibi ana tattara shi kai tsaye cikin kayayyaki ko tsarin. Dangane da adadin kwakwalwan kwamfuta da aka tattara a cikin tsarin guda ɗaya, nau'in gama gari shine 1 cikin 1 (BorgWarner), 6 a cikin 1 (Infineon), da sauransu, kuma wasu kamfanoni suna amfani da tsarin layi ɗaya na tube guda ɗaya.

Borgwarner Viper

Yana goyan bayan sanyaya ruwa mai gefe biyu da SiC-MOSFET

Infineon CoolSiC™ MOSFET kayayyaki

Ba kamar siliki ba,Modulolin siliki carbide suna aiki a mafi girman zafin jiki, kusan 200 ° C.

Yanayin zafi mai narkewa mai laushi mai laushi na gargajiya yana da ƙasa, ba zai iya biyan buƙatun zafin jiki ba. Saboda haka, silicon carbide kayayyaki sau da yawa amfani da low-zazzabi azurfa sintering walda tsari.

Bayan an kammala tsarin, ana iya amfani da shi zuwa tsarin sassan.

Tesla Model3 mai kula da motoci

Guntun dandali ya fito ne daga ST, kunshin ɓullo da kai da tsarin tuƙi na lantarki

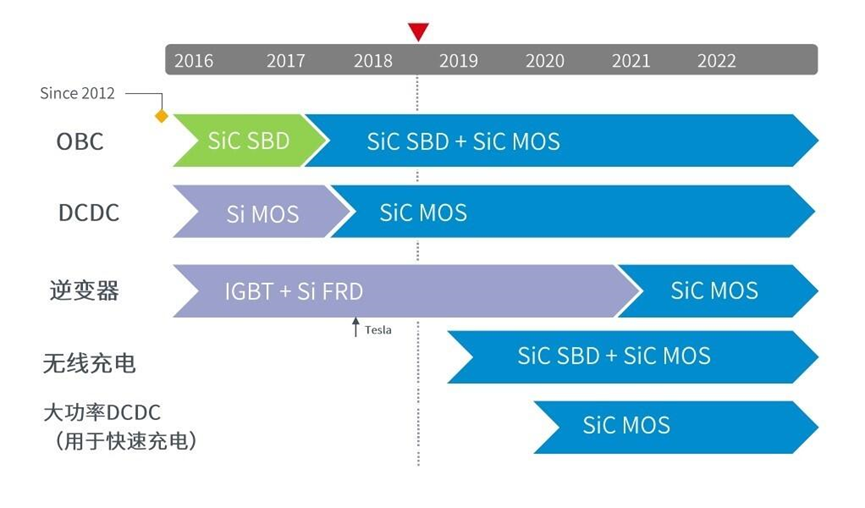

☆02 Matsayin aikace-aikacen SiC?

A cikin filin kera motoci, ana amfani da na'urorin wuta galibi a cikiDCDC, OBC, injin inverter, injin kwandishan inverter, caji mara waya da sauran sassawanda ke buƙatar saurin AC/DC (DCDC galibi yana aiki azaman sauyawa mai sauri).

Hoto: BorgWarner

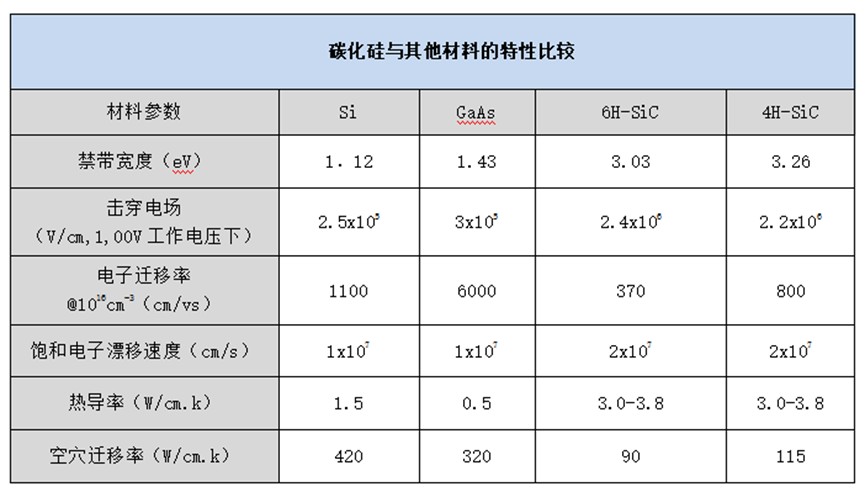

Idan aka kwatanta da kayan tushen silicon, kayan SIC sun fi girmaƘarfin fage mai tsananin dusar ƙanƙara(3×106V/cm),mafi kyawun halayen thermal(49W/mK) dafadi rata(3.26eV).

Faɗin tazarar band ɗin, ƙaramar ɗigowar halin yanzu kuma mafi girman inganci. Mafi kyawun halayen thermal, mafi girma da yawa na yanzu. Mafi ƙarfi da mahimmancin filin rushewar dusar ƙanƙara shine, ana iya inganta juriyar wutar lantarki na na'urar.

Sabili da haka, a fagen babban ƙarfin lantarki, MOSFETs da SBD waɗanda aka shirya ta kayan silicon carbide don maye gurbin IGBT na tushen silicon da ke da alaƙa da haɗin gwiwar FRD na iya haɓaka ƙarfi da inganci yadda yakamata,musamman a cikin babban yanayin aikace-aikacen aikace-aikacen don rage asarar sauyawa.

A halin yanzu, yana yiwuwa a cimma manyan aikace-aikace a cikin injin inverters, sannan OBC da DCDC suka biyo baya.

800V ƙarfin lantarki dandamali

A cikin dandali na ƙarfin lantarki na 800V, fa'idar babban mitar yana sa kamfanoni su fi son zaɓar mafita na SiC-MOSFET. Saboda haka, yawancin tsarin sarrafa lantarki na 800V na yanzu SiC-MOSFET.

Tsarin matakin dandamali ya haɗa daE-GMP na zamani, GM Otenergy - filin karba, Porsche PPE, da Tesla EPA.Sai dai samfuran dandamali na Porsche PPE waɗanda ba sa ɗaukar SiC-MOSFET a sarari (samfurin farko shine tushen IGBT na silica), sauran dandamalin abin hawa suna ɗaukar tsarin SiC-MOSFET.

Universal Ultra makamashi dandamali

Tsarin samfurin 800V ya fi,The Great Wall Salon iri Jiagirong, Beiqi pole Fox S HI version, manufa mota S01 da W01, Xiaopeng G9, BMW NK1, Changan Avita E11 ya ce zai kawo 800V dandamali, ban da BYD, Laantu, GAC 'an, Mercedes-Benz, sifili Run, FAW Red Flag, Volkswagen kuma ya ce 800V fasaha a cikin bincike.

Daga halin da ake ciki na odar 800V da aka samu ta hanyar Tier1 masu kaya,BorgWarner, Wipai Technology, ZF, United Electronics, da Huichuanduk an sanar da umarnin tuƙi na lantarki 800V.

400V ƙarfin lantarki dandamali

A cikin dandali na ƙarfin lantarki na 400V, SiC-MOSFET ya fi dacewa a cikin la'akari da babban iko da ƙarfin ƙarfi da inganci.

Irin su Motar Tesla Model 3 \ Y wanda aka samar da yawa a yanzu, ƙarfin kololuwar motar BYD Hanhou yana kusan 200Kw (Tesla 202Kw, 194Kw, 220Kw, BYD 180Kw), NIO kuma za ta yi amfani da samfuran SiC-MOSFET waɗanda za a fara daga ET7 kuma daga baya za a jera su. Mafi girman ƙarfin shine 240Kw (ET5 210Kw).

Bugu da kari, ta fuskar ingantaccen inganci, wasu masana'antu kuma suna binciken yuwuwar ambaliya na taimakon kayayyakin SiC-MOSFET.

Lokacin aikawa: Jul-08-2023