1 Gabatarwa

A cikin majalissar da'ira, ana fara bugu da manna mai siyar akan kushin da'ira, sa'an nan kuma ana lika kayan aikin lantarki daban-daban. A ƙarshe, bayan tanderun da aka sake kunnawa, ana narkar da ƙwanƙwasa da ke cikin manna kuma ana haɗa nau'ikan kayan aikin lantarki da pad ɗin da'irar don gane haɗuwar ƙananan ƙwayoyin lantarki. surfacemounttechnology (sMT) ana ƙara amfani da a high-yawa marufi kayayyakin, kamar tsarin matakin kunshin (siP), ballgridarray (BGA) na'urorin, da ikon danda Chip, square lebur fil-kasa kunshin (quad aatNo-lead, ake magana a kai a matsayin QFN).

Saboda halaye na solder manna waldi tsari da kuma kayan, bayan reflow waldi na wadannan manyan solder surface na'urorin, za a sami ramuka a cikin solder waldi yankin, wanda zai shafi da lantarki Properties, thermal Properties da inji Properties na samfurin Performance, kuma ko da kai ga samfurin gazawar, sabili da haka, don inganta solder manna reflow nazarin waldi rami ya zama dole ne a yi bincike da kuma warware wasu matsaloli na fasaha da bincike, da fasaha da bincike da bincike na wasu matsaloli. Solder ball waldi rami, da kuma samar da ingantattun mafita, al'ada solder manna reflow tsarin walda yankin na QFN mafi girma fiye da 10mm2 ko waldi yankin mafi girma 6 mm2 ta danda guntu bayani ne rashi.

Yi amfani da walƙiya na Preformsolder da walƙiya na murhun wuta don inganta ramin walda. Solder da aka riga aka kera yana buƙatar kayan aiki na musamman don nuna juzu'i. Misali, guntu yana kashewa kuma an karkatar da shi da gaske bayan an sanya guntu kai tsaye akan siyar da aka riga aka kera. Idan guntu mai jujjuyawa ya sake fitowa sannan kuma ya nuna, tsarin yana ƙaruwa da saukowa biyu, kuma farashin kayan siyar da aka ƙera da kayan juyi ya fi na manna solder yawa.

Kayan aiki na reflux Vacuum ya fi tsada, ƙarfin injin injin mai zaman kansa yana da ƙasa sosai, aikin farashi ba shi da yawa, kuma matsalar fashewar kwano yana da mahimmanci, wanda shine muhimmin mahimmanci a cikin aikace-aikacen samfura masu yawa da ƙanana. A cikin wannan takarda, bisa tsarin al'ada solder manna reflow walda, wani sabon sakandare reflow tsarin da aka ɓullo da kuma gabatar da su don inganta walda rami da warware matsalolin bonding da roba hatimin fatattaka lalacewa ta hanyar walda rami.

2 Solder manna bugu reflow waldi rami da samar inji

2.1 Kogon walda

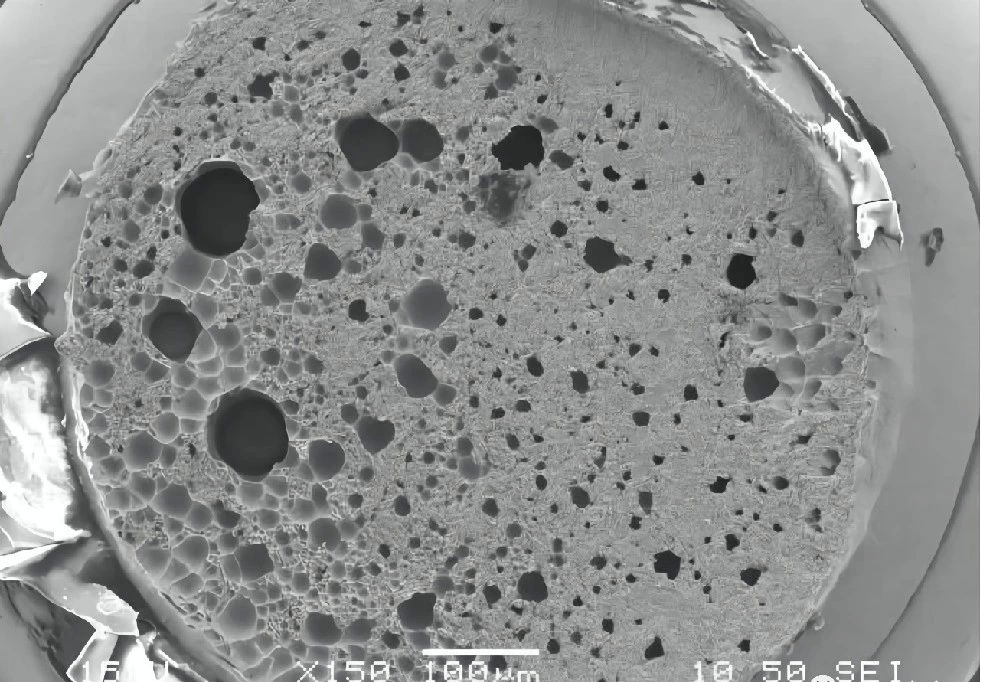

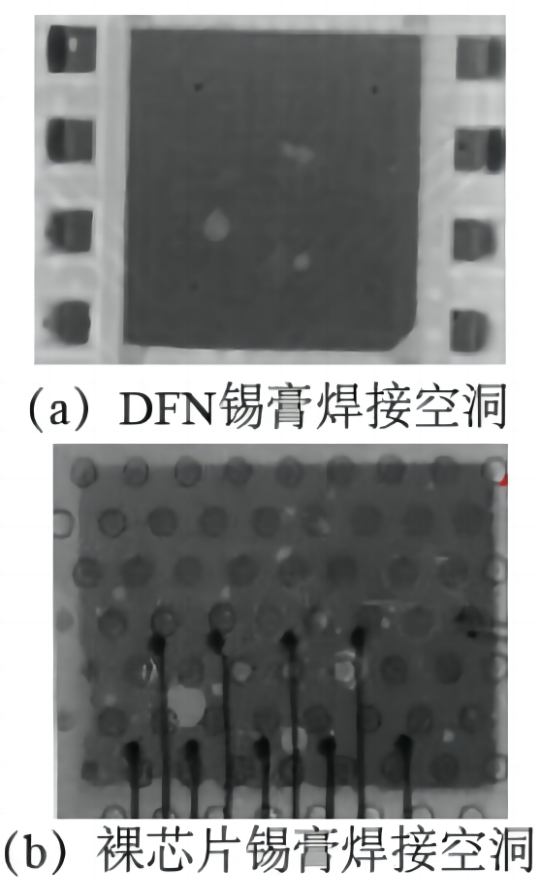

Bayan sake kunna walda, an gwada samfurin a ƙarƙashin x-ray. An gano ramukan da ke yankin walda mai launi mai sauƙi saboda rashin isassun solder a cikin layin walda, kamar yadda aka nuna a hoto 1.

Gano X-ray na ramin kumfa

2.2 Tsarin tsari na rami na walda

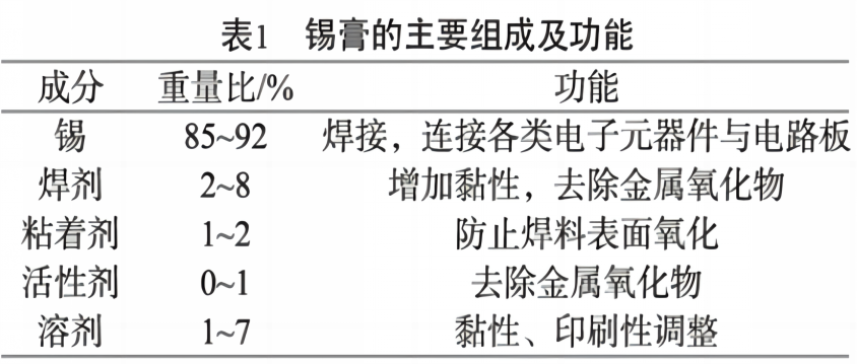

Ɗaukar sAC305 solder manna a matsayin misali, babban abun da ke ciki da aikin ana nuna su a cikin Tebura 1. An haɗa juzu'i da ƙullun kwano tare a siffar manna. Matsakaicin nauyin tin solder zuwa juyi shine kusan 9:1, kuma girman girman shine kusan 1:1.

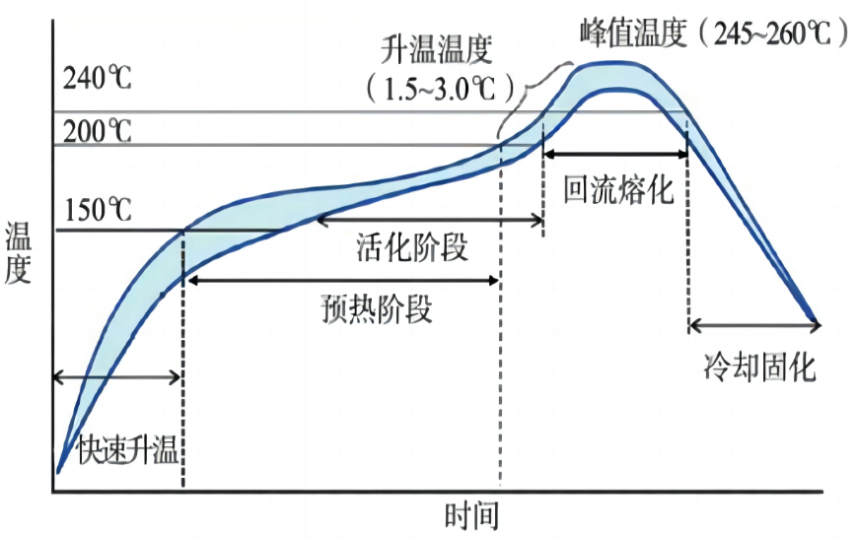

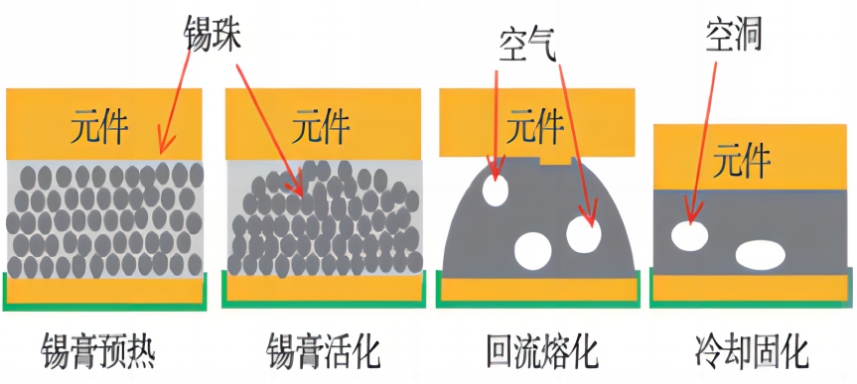

Bayan an bugu da manna solder da kayan aikin lantarki daban-daban, manna mai solder zai yi matakai huɗu na preheating, kunnawa, reflux da sanyaya lokacin da ya wuce ta cikin tanderun reflux. Halin manna mai siyar kuma ya bambanta da yanayin zafi daban-daban a matakai daban-daban, kamar yadda aka nuna a hoto na 2.

Bayanin bayanin martaba na kowane yanki na sake kwarara saida

A cikin preheating da kunnawa matakin, maras tabbas abubuwan da ke cikin juzu'i a cikin manna solder za su kasance masu canzawa zuwa gas lokacin da aka yi zafi. A lokaci guda kuma, za a samar da iskar gas lokacin da aka cire oxide a saman shimfidar walda. Wasu daga cikin waɗannan iskar gas za su rikiɗe su bar manna mai siyar, kuma ƙullun masu siyar za su kasance damtse saboda jujjuyawa. A cikin reflux mataki, sauran juyi a cikin solder manna zai ƙafe da sauri, da tin beads za su narke, wani karamin adadin juyi maras tabbas gas da kuma mafi yawan iska tsakanin tin beads ba za a tarwatsa a cikin lokaci, da kuma saura a cikin narkakkar tin da kuma karkashin tashin hankali na narkakkar da tin ne hamburger pa sandwich tsarin da kuma kewaye da wutar lantarki da aka nannade da lantarki tsarin da kuma da'irar da aka nannade da wutar lantarki da lantarki tsarin da kuma da'irar. tin ruwa yana da wahalar tserewa kawai ta hanyar buoyancy na sama Lokacin narkewa na sama gajere ne. Lokacin da narkakkar ɗin ta huce kuma ta zama daskararrun daskararru, ƙoramu suna fitowa a cikin layin walda kuma ana samun ramukan saida, kamar yadda aka nuna a hoto na 3.

Jadawalin tsari na fanko wanda aka samar ta hanyar walda mai sake kwarara

Tushen dalilin rami na walda shi ne cewa iskar ko iskar gas da ke naɗe a cikin man da ake solder bayan narkewa ba a fitar da shi gaba ɗaya. Abubuwan da ke haifar da tasiri sun haɗa da kayan daɗaɗɗen solder, siffar bugu na solder, adadin bugu na solder, zafin jiki na reflux, lokacin reflux, girman walda, tsarin da sauransu.

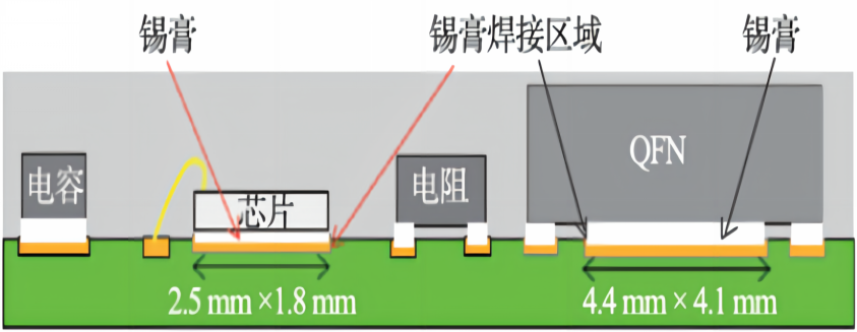

3. Tabbatar da tasiri dalilai na solder manna bugu reflow waldi ramukan

Anyi amfani da gwaje-gwajen guntu na QFN don tabbatar da manyan abubuwan da ke haifar da sake kwarara walda, da kuma nemo hanyoyin inganta ɓarna walda wanda aka buga ta manna. QFN da danda guntu solder manna reflow waldi samfurin profile da aka nuna a cikin Hoto 4, QFN waldi surface size ne 4.4mmx4.1mm, waldi surface ne tinned Layer (100% tsarki tin); Girman walda na guntun danda shine 3.0mmx2.3mm, Layer walda yana sputtered nickel-vanadium bimetallic Layer, kuma saman saman shine vanadium. Kushin walda na substrate ya kasance mai nickel-palladium zinare mara amfani, kuma kauri shine 0.4μm/0.06μm/0.04μm. SAC305 solder manna da ake amfani, da solder manna bugu kayan aiki ne DEK Horizon APIx, da reflux makera kayan aiki ne BTUPyramax150N, da x-ray kayan aiki ne DAGExD7500VR.

QFN da zanen walda na guntu mara tushe

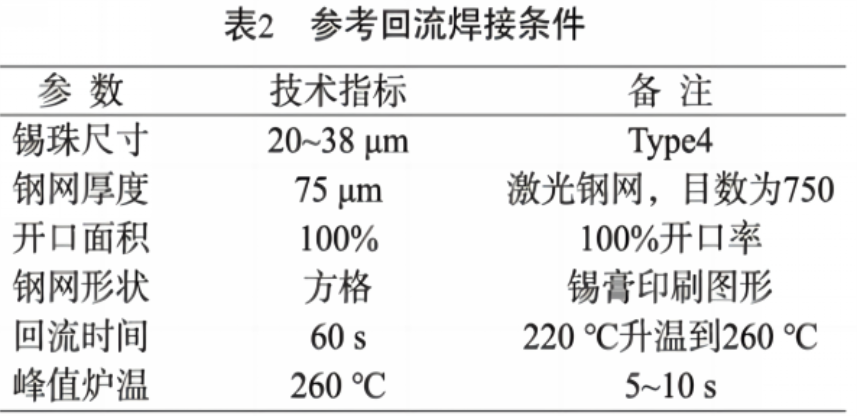

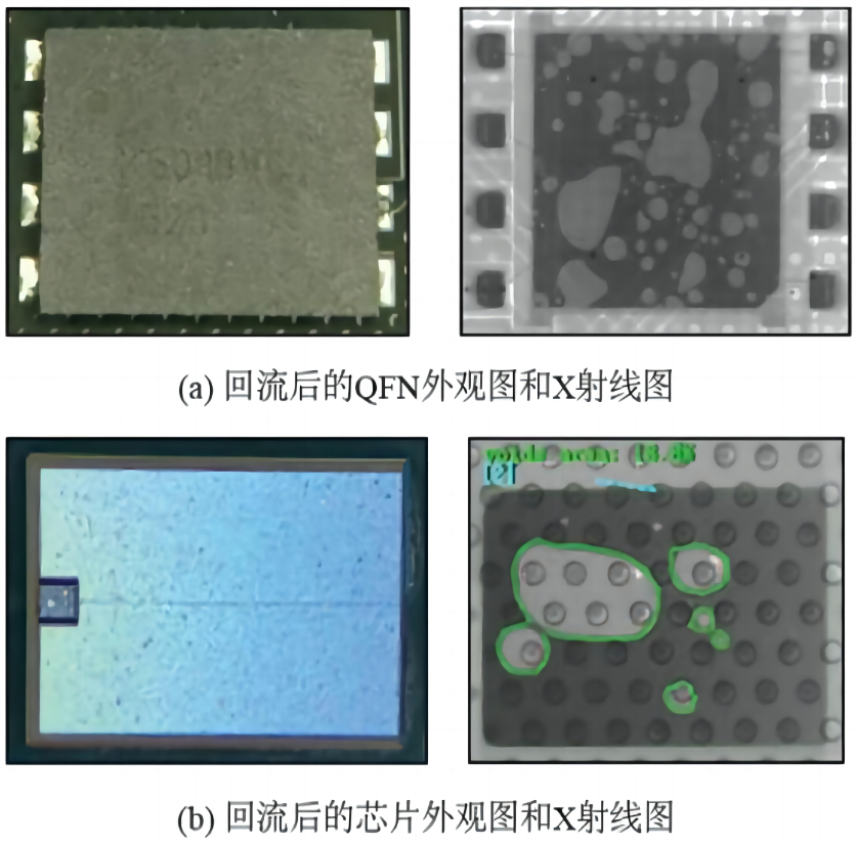

Don sauƙaƙe kwatancen sakamakon gwaji, an sake yin walda a ƙarƙashin sharuɗɗan da ke cikin Tebur 2.

Teburin yanayin walda ya sake kwarara

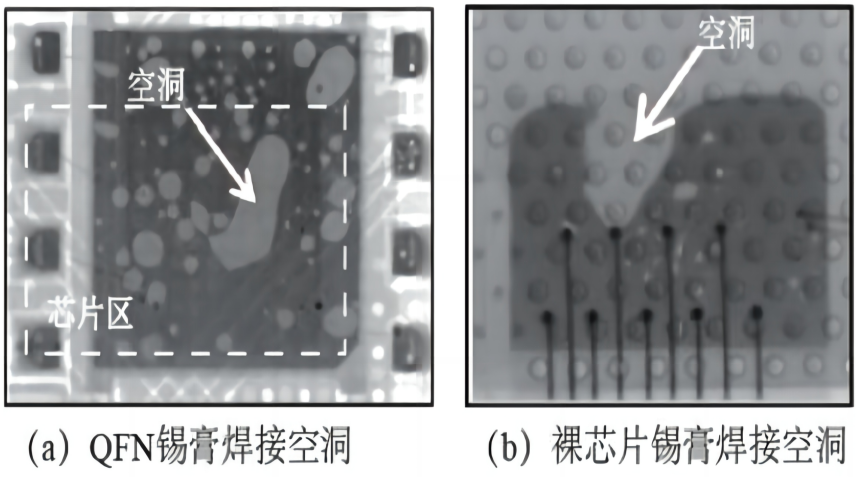

Bayan da aka kammala hawan sama da waldawar sake kwarara, an gano layin walda ta hanyar X-ray, kuma an gano cewa akwai manyan ramuka a cikin shimfidar walda a kasan QFN da guntu mara tushe, kamar yadda aka nuna a hoto na 5.

QFN da Chip Hologram (X-ray)

Tunda girman gwangwani, kaurin ragar ƙarfe, ƙimar buɗewa, siffar ragar karfe, lokacin reflux da zafin jiki na tanderu duk za su yi tasiri ga ɓarna walda, akwai abubuwa da yawa masu tasiri, waɗanda gwajin DOE za su tabbatar kai tsaye, kuma adadin ƙungiyoyin gwaji za su yi girma sosai. Wajibi ne a hanzarta dubawa da kuma tantance manyan abubuwan da ke tasiri ta hanyar gwajin kwatancen daidaitawa, sannan a kara inganta manyan abubuwan da ke tasiri ta hanyar DOE.

3.1 Girman ramukan solder da solder manna kwano beads

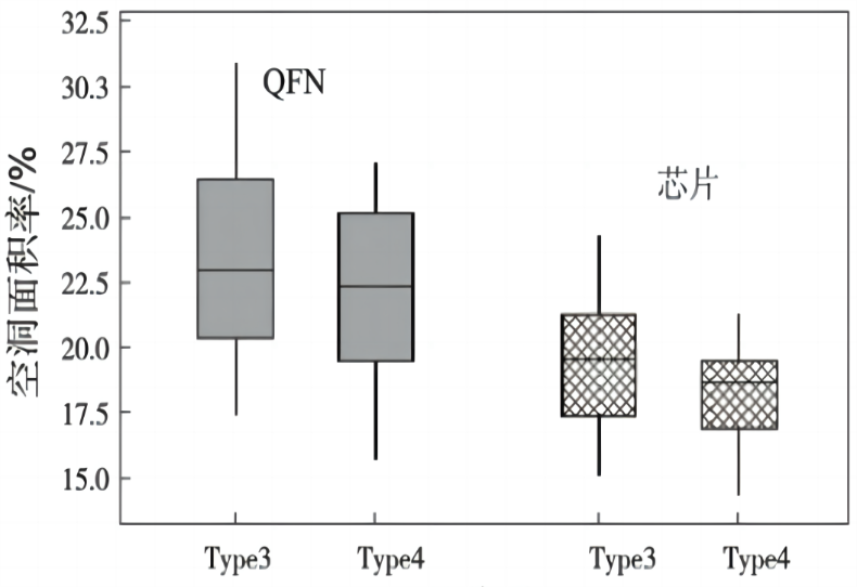

Tare da nau'in 3 (girman bead 25-45 μm) SAC305 gwajin manna solder, wasu yanayi ba su canzawa. Bayan sake dawowa, ana auna ramukan da ke cikin Layer ɗin solder kuma idan aka kwatanta da manna nau'in 4. An gano cewa ramuka a cikin mai siyarwa ba su da bambanci sosai tsakanin nau'ikan kayan siyarwa guda biyu, wanda ba a sanye da tasiri daban-daban ba, kamar yadda aka nuna a cikin siffa daban-daban. 6 Kamar yadda aka nuna.

Kwatanta ƙarfe tin foda ramukan da daban-daban barbashi masu girma dabam

3.2 Kauri na rami na walda da ragar ƙarfe da aka buga

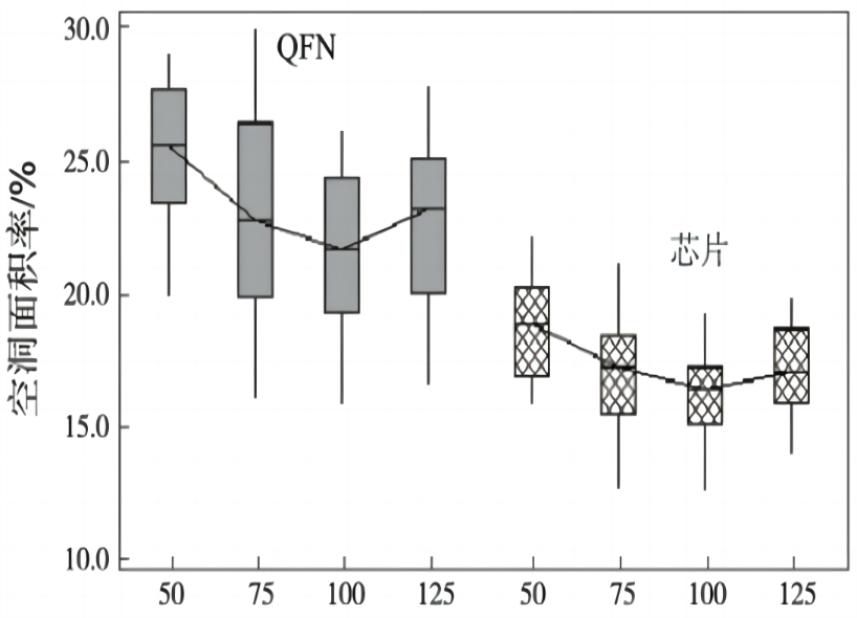

Bayan sake kwarara, an auna wurin rami na welded Layer tare da bugu na raga na karfe tare da kauri na 50 μm, 100 μm da 125 μm, kuma wasu yanayi sun kasance ba su canza ba. An gano cewa tasirin kauri daban-daban na ragar karfe (manna mai siyar) akan QFN an kwatanta shi da na bugu na ragar karfe tare da kauri na 75 μm Yayin da kaurin ragar karfe ya karu, yankin rami yana raguwa sannu a hankali. Bayan kai wani kauri (100μm), yankin rami zai koma baya ya fara karuwa tare da karuwar kaurin ragar karfe, kamar yadda aka nuna a hoto na 7.

Wannan yana nuna cewa lokacin da adadin manna ya karu, kwano mai ruwa tare da reflux yana rufe shi da guntu, kuma madaidaicin tseren iska yana kunkuntar a bangarorin hudu. Lokacin da aka canza adadin manna mai siyar, madaidaicin iskar gudun hijira kuma yana ƙaruwa, kuma fashewar iska nan take da ke naɗe da gwangwanin ruwa ko iskar gas mai saurin gudu zai haifar da tin ɗin ruwa ya fantsama a kusa da QFN da guntu.

Gwajin ya gano cewa tare da karuwar kaurin ragar karfen, fashewar kumfa da ke haifar da kubucewar iska ko iskar gas shima zai karu, kuma yuwuwar yada kwano a kusa da QFN da guntu shima zai karu daidai.

Kwatanta ramuka a ragar karfe na kauri daban-daban

3.3 Rabon yanki na rami mai walda da buɗaɗɗen ragar ƙarfe

An gwada ragamar ƙarfe da aka buga tare da ƙimar buɗewa na 100%, 90% da 80%, kuma wasu yanayi sun kasance ba su canza ba. Bayan sake kwarara, an auna wurin rami na welded Layer kuma idan aka kwatanta da bugu na raga na karfe tare da adadin buɗewa 100%. An gano cewa babu wani gagarumin bambanci a cikin rami na welded Layer a ƙarƙashin yanayin buɗewar adadin 100% da 90% 80%, kamar yadda aka nuna a hoto na 8.

Cavity kwatanta daban-daban bude yankin na daban-daban karfe raga

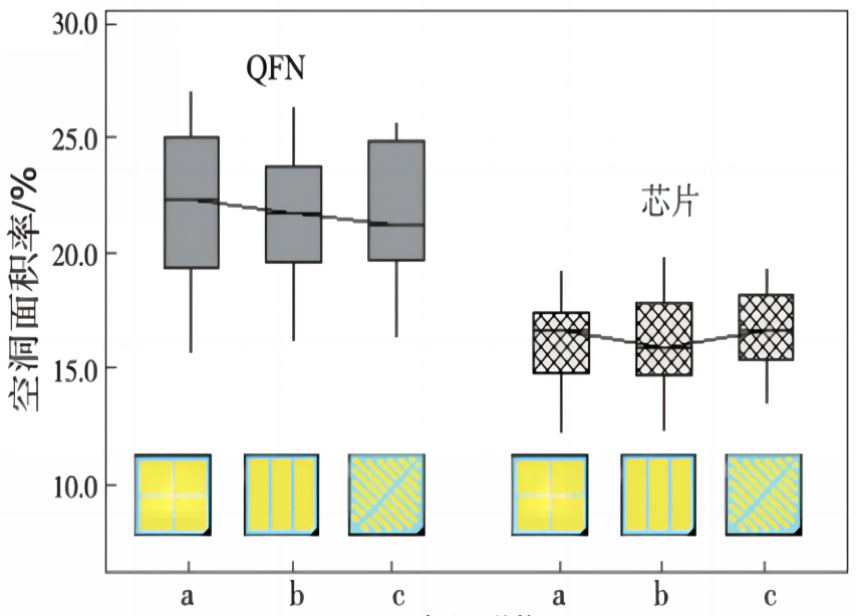

3.4 Welded rami da buga karfe raga siffar

Tare da gwajin siffar bugu na manna mai siyar da tsiri b da grid mai karkata, wasu yanayi ba su canzawa. Bayan sake kwarara, ana auna kogon layin walda kuma idan aka kwatanta da sifar bugu na grid a. An gano cewa babu wani gagarumin bambanci a cikin kogon walda a ƙarƙashin yanayin grid, tsiri da grid mai karkata, kamar yadda aka nuna a hoto na 9.

Kwatanta ramuka a cikin nau'ikan buɗewa daban-daban na ragar ƙarfe

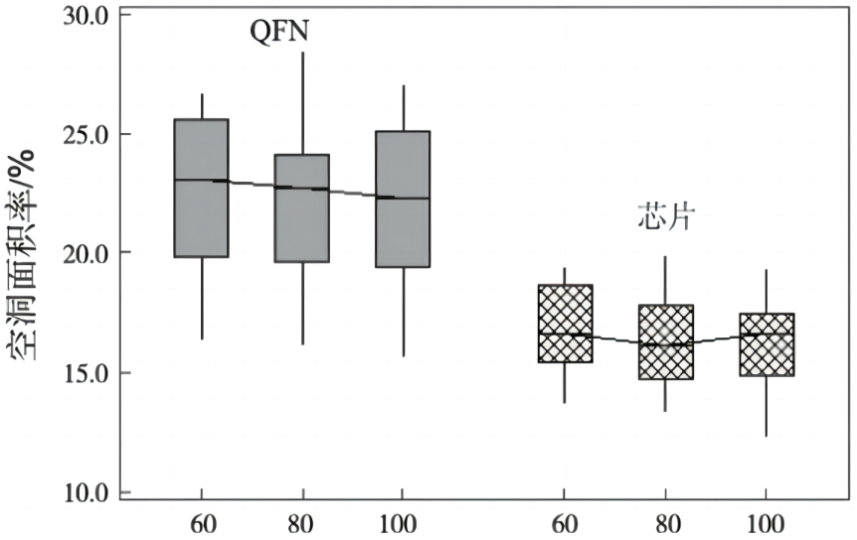

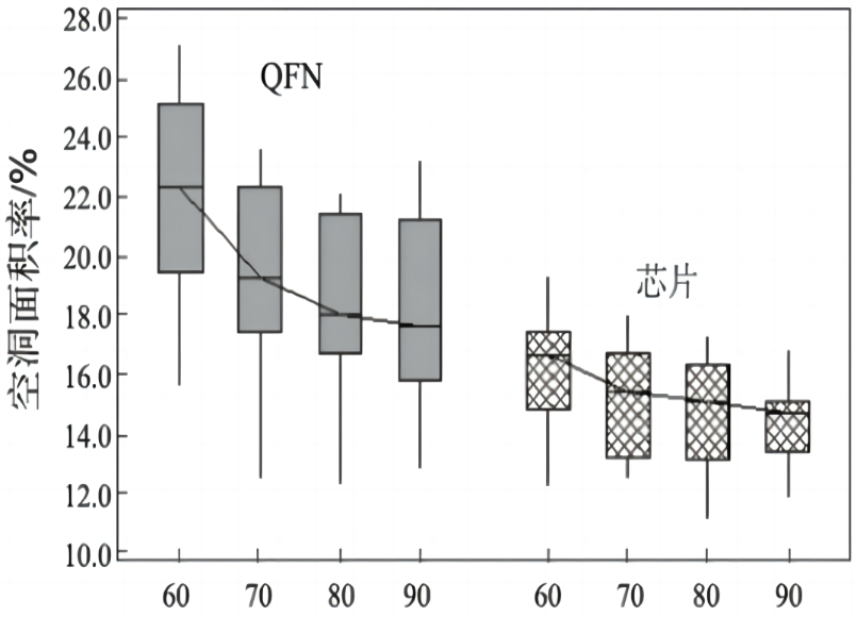

3.5 Welding cavity da reflux lokaci

Bayan tsawan lokaci na reflux (70 s, 80 s, 90 s) gwajin, wasu yanayi sun kasance ba su canzawa, an auna rami a cikin Layer na walda bayan reflux, kuma idan aka kwatanta da lokacin reflux na 60 s, an gano cewa tare da karuwar lokacin reflux, yankin ramin walda ya ragu, amma raguwa tare da raguwar raguwar lokacin da aka nuna a hankali 1. idan ba a sami isasshen lokacin reflux ba, ƙara lokacin reflux yana ba da damar cikar iskar da aka naɗe a cikin narkakkar ruwa gwangwani, amma bayan lokacin reflux ya ƙaru zuwa wani lokaci, iskar da ke naɗe a cikin tin ruwa yana da wuyar sake ambaliya. Lokacin reflux yana ɗaya daga cikin abubuwan da ke shafar kogon walda.

Kwatanta mara kyau na tsawon lokacin reflux daban-daban

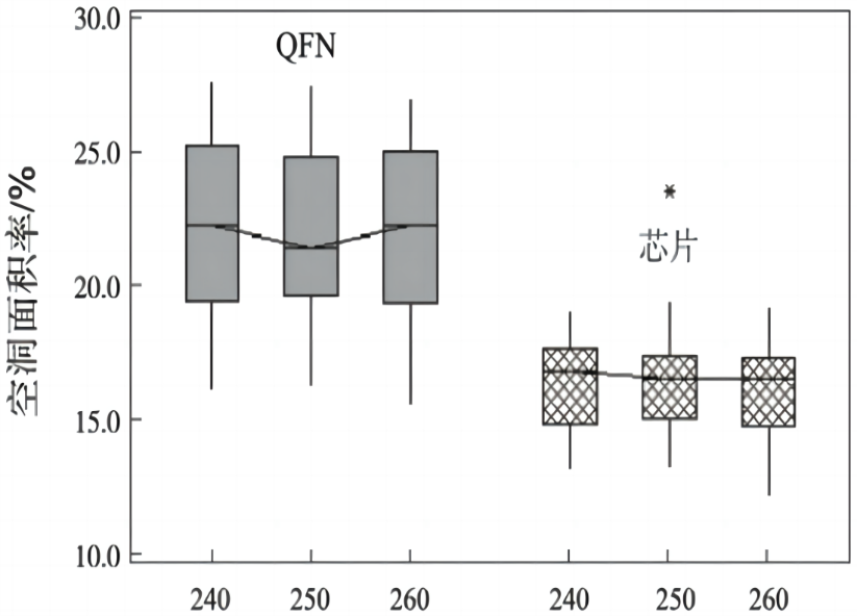

3.6 Welding rami da kololuwar tanderun zafin jiki

Tare da 240 ℃ da 250 ℃ ganiya tanderu zafin jiki gwajin da sauran yanayi canzawa, da rami yankin na welded Layer da aka auna bayan reflow, kuma idan aka kwatanta da 260 ℃ ganiya tanderu zafin jiki, an gano cewa a karkashin daban-daban ganiya tanderu zafin jiki yanayi, da kogon na welded Layer na QFN nuna muhimmanci ba ya nuna a cikin guntu. zafin wutar tanderu ba shi da wani tasiri a zahiri akan QFN da rami a cikin layin walda na guntu, wanda ba abu bane mai tasiri.

Kwatanta mara kyau na yanayin zafi daban-daban

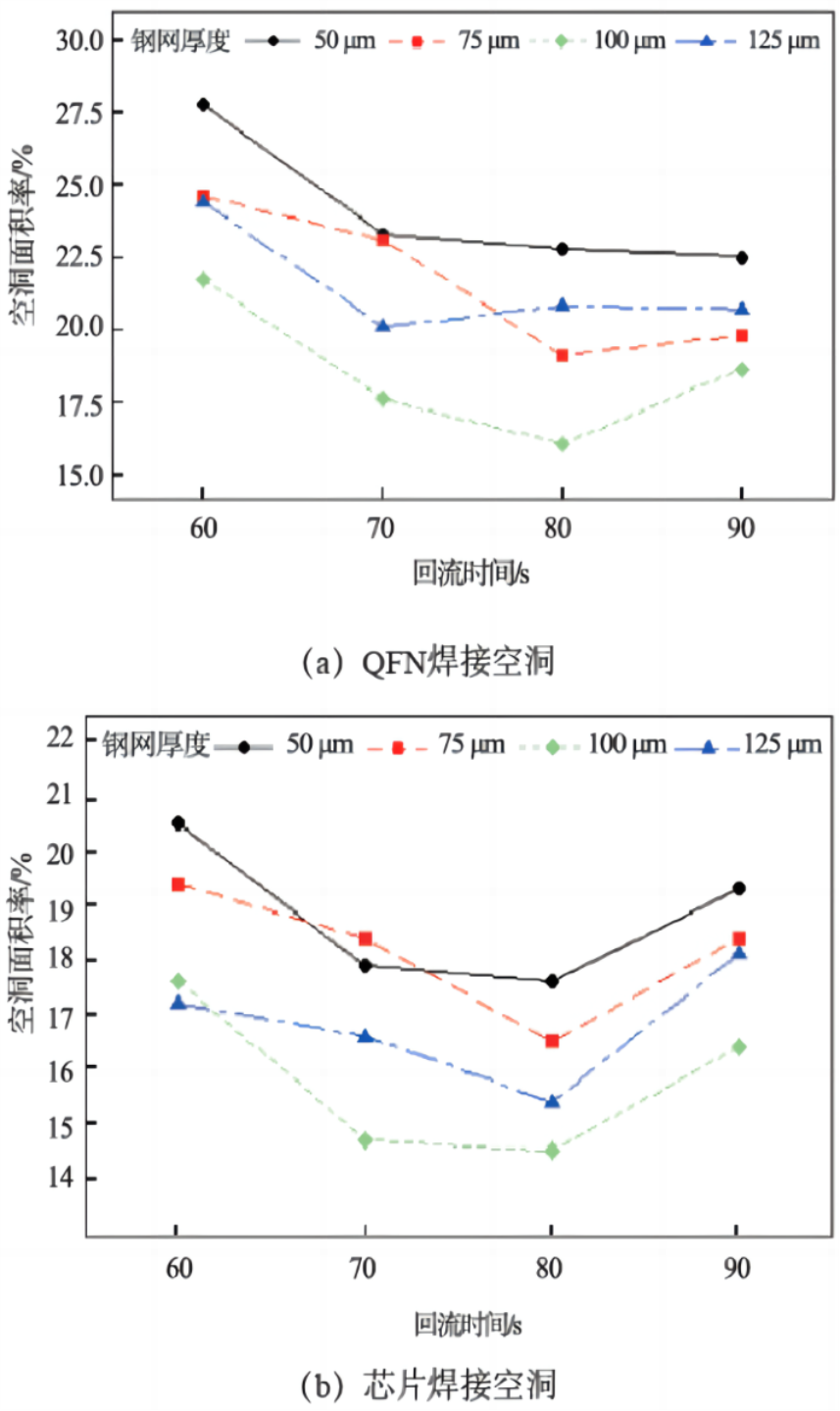

Gwaje-gwajen da ke sama suna nuna cewa mahimman abubuwan da ke shafar rami na weld na QFN da guntu sune lokacin reflux da kauri na raga.

4 Solder manna bugu reflow waldi kara inganta

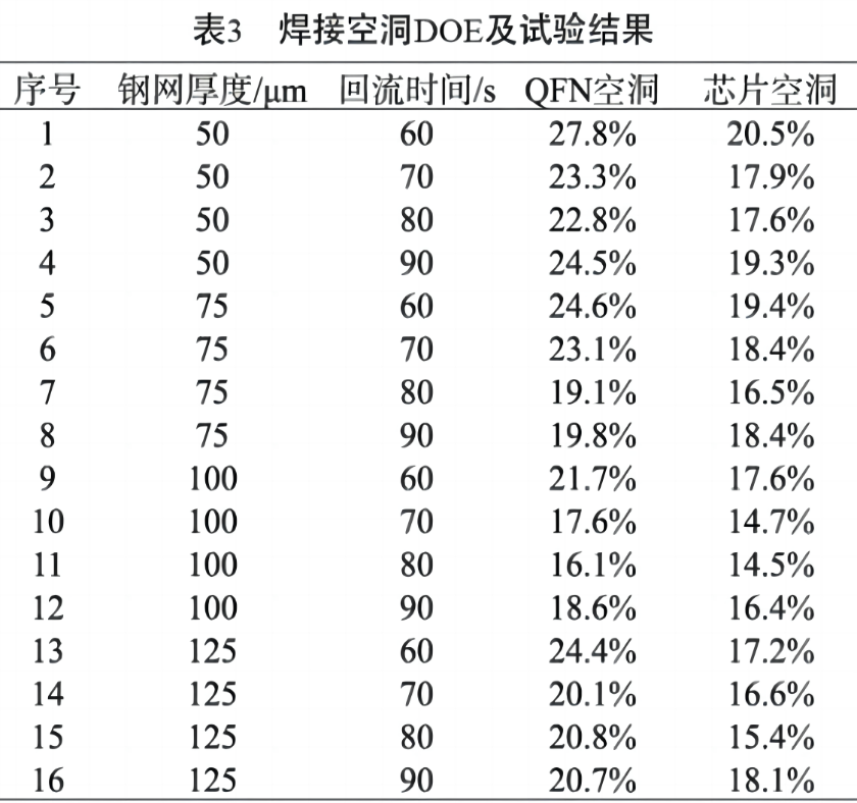

4.1 DOE gwajin don inganta kogin walda

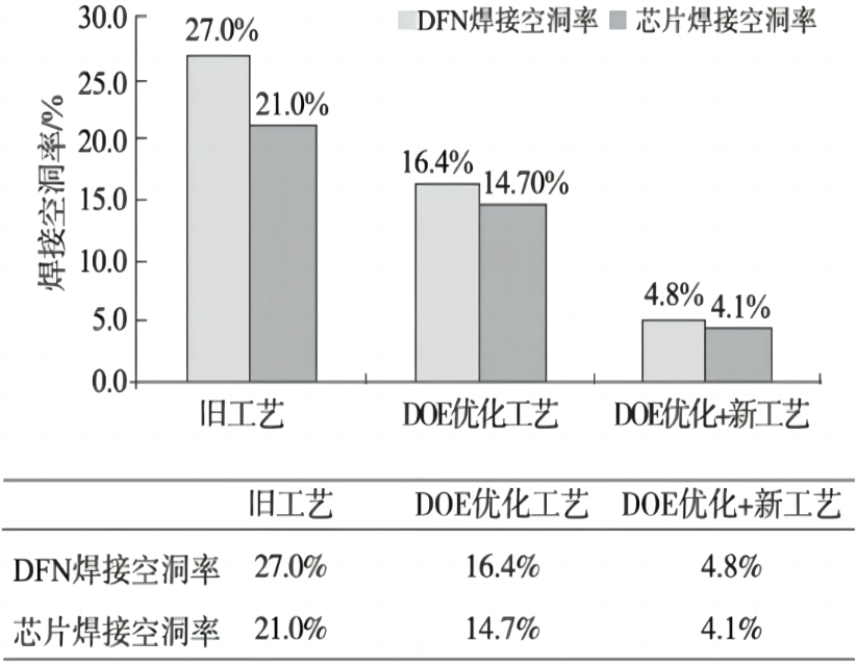

Ramin da ke cikin walda na QFN da guntu an inganta shi ta hanyar gano mafi kyawun ƙimar manyan abubuwan da ke tasiri (lokacin reflux da kaurin ragar ƙarfe). The solder manna ya SAC305 type4, da karfe raga siffar da aka Grid irin (100% bude digiri), ganiya tanderu zafin jiki ne 260 ℃, da sauran gwajin yanayi sun kasance iri daya da na gwajin kayan aiki. DOE gwajin da sakamakon da aka nuna a cikin Table 3. Tasirin karfe raga kauri da reflux lokaci a kan QFN da guntu walda ramukan da aka nuna a cikin Hoto 12. Ta hanyar hulɗar bincike na babban tasiri dalilai, An gano cewa yin amfani da 100 μm karfe raga kauri da 80 s reflux lokaci na iya rage girman walda guntu na QFN. An rage ƙimar rami na walda na QFN daga matsakaicin 27.8% zuwa 16.1%, kuma an rage ƙimar rami na walda daga matsakaicin 20.5% zuwa 14.5%.

A cikin gwajin, an samar da samfuran 1000 a ƙarƙashin ingantattun yanayi (kauri 100 μm karfe raga, lokacin reflux 80s), kuma an auna ƙimar rami na walda na 100 QFN da guntu ba da gangan ba. Matsakaicin ƙimar rami na walda na QFN ya kasance 16.4%, kuma matsakaicin matsakaicin rami na walda shine 14.7% Adadin rami na walda na guntu da guntu a fili an rage su.

4.2 Sabon tsari yana inganta rami na walda

Ainihin samar da yanayin da gwajin nuna cewa lokacin da waldi rami yankin a kasa na guntu ne kasa da 10%, guntu rami matsayi fatattaka matsalar ba zai faru a lokacin gubar bonding da gyare-gyare. Ma'auni na tsari wanda DOE ya inganta ba zai iya biyan buƙatun nazari da warware ramukan da ke cikin walda na al'ada na al'ada ba, kuma ƙimar yanki na walda na guntu yana buƙatar ƙara ragewa.

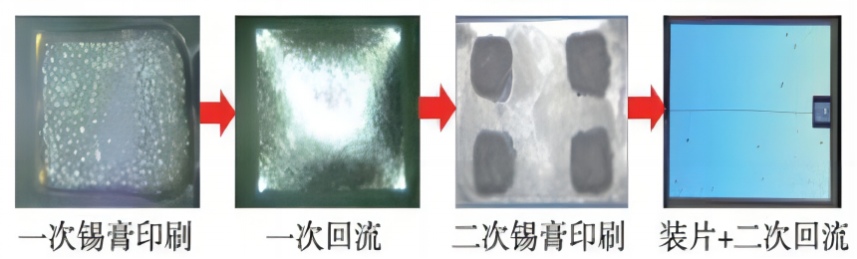

Tun da guntu da aka lulluɓe akan mai siyar yana hana iskar gas da ke cikin mai siyar tserewa, ƙimar ramin da ke ƙasan guntu yana ƙara ragewa ta hanyar kawarwa ko rage iskar gas mai rufi. Wani sabon tsari na sake walda walda tare da bugu guda biyu na solder bugu: bugu na manna solder ɗaya, sake kwarara ɗaya wanda baya rufe QFN da guntu mara amfani yana fitar da iskar gas a cikin solder; Ana nuna takamaiman tsari na bugu na solder na biyu, faci da reflux na biyu a cikin hoto 13.

Lokacin da 75μm lokacin farin ciki solder manna da aka buga a karon farko, mafi yawan gas a cikin solder ba tare da guntu murfin tserewa daga saman, da kuma kauri bayan reflux ne game da 50μm. Bayan kammala reflux na farko, ana buga ƙananan murabba'ai a saman solder mai sanyaya mai sanyaya (domin rage adadin manna mai, rage adadin iskar gas, rage ko kawar da spatter), da manna solder tare da kauri na 50 μm (sakamakon gwajin da ke sama ya nuna cewa 100 μm shine mafi kyawun bugu, don haka kauri na 1.5. μm=50 μm), sa'an nan kuma shigar da guntu, sa'an nan kuma komawa ta 80 s. Kusan babu wani rami a cikin solder bayan bugu na farko da sake fitowa, sannan manna a bugu na biyu karami ne, ramin walda kuma karami ne, kamar yadda aka nuna a hoto na 14.

Bayan bugu biyu na solder manna, m zane

4.3 Tabbatar da tasirin walda

Samar da 2000 kayayyakin (kauri na farko bugu karfe raga ne 75 μm, da kauri na biyu bugu karfe raga ne 50 μm), sauran yanayi ba canzawa, bazuwar ma'auni na 500 QFN da guntu waldi rami kudi, gano cewa sabon tsari bayan na farko reflux no rami, bayan na biyu refluxity ne matsakaicin kashi 8%. Adadin rami na walda na guntu shine 4.1%. Idan aka kwatanta da asali guda-manna bugu waldi tsari da DOE ingantacce tsari, da walda rami da muhimmanci rage, kamar yadda aka nuna a Figure 15. Babu guntu fasa da aka samu bayan aikin gwaje-gwaje na duk kayayyakin.

5 Takaitawa

The inganta solder manna bugu adadin da reflux lokaci na iya rage waldi rami yankin, amma waldi rami kudi ne har yanzu manyan. Yin amfani da fasahohin walƙiya na walda guda biyu na solder bugu na iya yin tasiri sosai da haɓaka ƙimar rami na walda. Yankin walda na guntuwar guntuwar dandali na QFN na iya zama 4.4mm x4.1mm da 3.0mm x2.3mm bi da bi a cikin samar da yawan jama'a Ana sarrafa ƙimar raƙuman walda a ƙasa da 5%, wanda ke haɓaka inganci da amincin reflow waldi. Binciken da ke cikin wannan takarda yana ba da muhimmiyar magana don inganta matsalar rami na walda na babban yanki na walda.

Lokacin aikawa: Jul-05-2023