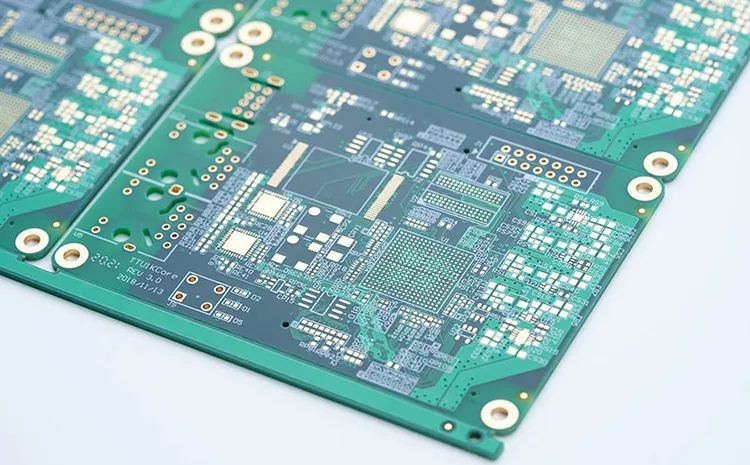

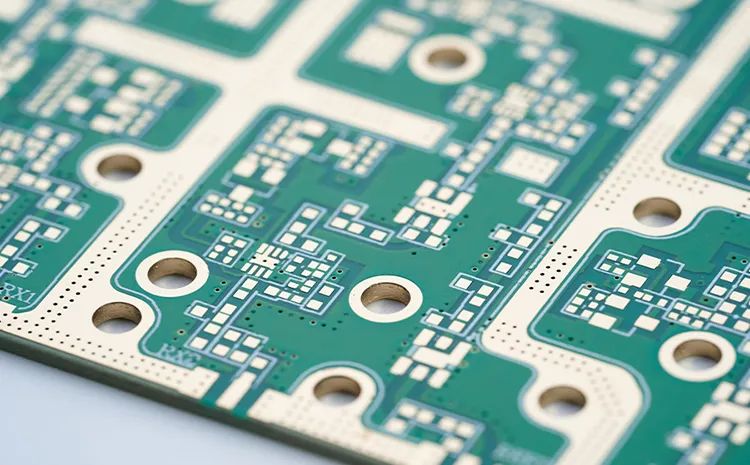

PCB saboda madaidaicin sa da tsattsauran ra'ayi, buƙatun lafiyar muhalli na kowane taron bita na PCB yana da girma sosai, kuma wasu tarurrukan har ma suna fuskantar “hasken rawaya” duk tsawon yini. Humidity, kuma yana ɗaya daga cikin alamun da ke buƙatar kulawa sosai, a yau za mu yi magana game da tasirin zafi akan PCBA.

Muhimmancin "humidity"

Danshi alama ce mai matukar mahimmanci kuma mai tsananin sarrafawa a cikin tsarin masana'anta. Ƙananan zafi na iya haifar da bushewa, ƙãra ESD, ƙãra matakan ƙura, mafi sauƙi toshe buɗaɗɗen samfuri, da ƙãra lalacewa ta samfur. Ayyukan ya tabbatar da cewa ƙananan zafi zai shafi kai tsaye kuma ya rage ƙarfin samarwa. Yayi tsayi da yawa zai sa kayan ya sha danshi, yana haifar da delamination, tasirin popcorn, da ƙwallan solder. Danshi kuma yana rage ƙimar TG na kayan kuma yana ƙara haɓakar warping yayin sake walda.

Gabatarwa ga danshi

Kusan dukkan filaye masu ƙarfi (kamar ƙarfe, gilashi, yumbu, silicon, da sauransu) suna da rigar da ke shayar da ruwa (launi ɗaya ko multimolecular Layer) wanda ke bayyana lokacin da zafin saman saman ya yi daidai da zafin raɓa na kewayen iska (dangane da zafin jiki, zafi, da iska). Tashin hankali tsakanin ƙarfe da ƙarfe yana ƙaruwa tare da raguwar zafi, kuma a dangi zafi na 20% RH da ƙasa, juzu'in ya ninka sau 1.5 sama da yanayin zafi na 80% RH.

Wuraren da ke sha ruwa mai ƙarfi ko danshi (resins epoxy resins, robobi, fluxes, da dai sauransu) suna shanye waɗannan yadudduka masu sha, kuma ko da lokacin da zafin jiki ya kasance ƙasa da ma'anar raɓa (condensation), abin sha mai ɗaukar ruwa mai ɗauke da ruwa ba a iya gani a saman kayan.

Ruwa ne a cikin yadudduka masu shayar da kwayoyin halitta guda ɗaya akan waɗannan saman waɗanda ke ratsawa cikin na'urar rufewa ta filastik (MSD), kuma lokacin da yadudduka masu shayarwa guda ɗaya suka kusanci yadudduka 20 a cikin kauri, danshin da waɗannan yaduddukan shayarwa guda ɗaya ke sha a ƙarshe yana haifar da tasirin popcorn yayin sake dawo da siyarwa.

Tasirin zafi a lokacin masana'anta

Danshi yana da tasiri da yawa akan samarwa da masana'antu. Gabaɗaya, zafi ba ya iya gani (sai dai ƙarar nauyi), amma sakamakon shine pores, voids, solder spatter, solder balls, da kuma kasa-cika kura.

A cikin kowane tsari, kula da danshi da zafi yana da matukar muhimmanci, idan bayyanar jikin jiki ba shi da kyau, samfurin da aka gama bai cancanta ba. Sabili da haka, taron bitar na yau da kullun ya kamata ya tabbatar da cewa ana sarrafa danshi da zafi na farfajiyar ƙasa da kyau don tabbatar da cewa alamun muhalli a cikin tsarin samar da samfuran da aka gama suna cikin kewayon ƙayyadaddun.

Lokacin aikawa: Maris 26-2024