【 Dry kaya】 Bincike mai zurfi na SMT me yasa ake amfani da manne ja? (2023 Essence Edition), kun cancanci shi!

SMT m, kuma aka sani da SMT m, SMT ja adhesive, yawanci ja (kuma rawaya ko fari) manna a ko'ina rarraba tare da hardener, pigment, sauran ƙarfi da sauran adhesives, yafi amfani da su gyara sassa a kan bugu allo, gaba ɗaya rarraba ta hanyar rarraba ko karfe allo bugu hanyoyin. Bayan an haɗa abubuwan da aka gyara, sanya su a cikin tanda ko reflow tanderu don dumama da taurin. Bambance-bambancen da ke tsakaninsa da man da ake sayar da shi shi ne, ana warkewa bayan zafi, zafin zafinsa ya kai 150 ° C, kuma ba zai narke ba bayan ya sake dumama, wato tsarin taurin zafi na facin ba zai iya jurewa ba. Tasirin amfani da mannen SMT zai bambanta saboda yanayin warkewar thermal, abin da aka haɗa, kayan aikin da ake amfani da su, da yanayin aiki. Ya kamata a zaɓi manne bisa ga tsarin taron hukumar da'ira (PCBA, PCA) da aka buga.

Halaye, aikace-aikace da kuma bege na SMT patch m

SMT ja manne wani nau'i ne na fili na polymer, manyan abubuwan da aka gyara su ne kayan tushe (wato, babban kayan ƙwayoyin ƙwayoyin cuta), filler, wakili na warkewa, sauran ƙari da sauransu. SMT ja manne yana da danko fluidity, zazzabi halaye, wetting halaye da sauransu. Dangane da wannan sifa ta jan man leli, a cikin samarwa, manufar yin amfani da jan manne shine sanya sassan su manne da saman PCB don hana shi fadowa. Saboda haka, da faci m ne mai tsarki amfani da ba da muhimmanci tsari kayayyakin, da kuma yanzu tare da ci gaba da inganta PCA zane da kuma tsari, ta hanyar rami reflow da biyu-gefe reflow waldi an gane, da PCA hawa tsari ta yin amfani da faci m yana nuna wani Trend na kasa da kasa.

Dalilin amfani da mannen SMT

① Hana abubuwan da aka gyara daga fadowa a cikin siyar da igiyar ruwa (tsarin sayar da igiyar ruwa). Lokacin amfani da siyar da igiyar igiyar ruwa, ana gyara abubuwan da aka gyara akan allon da aka buga don hana abubuwan da aka gyara daga faɗuwa a lokacin da allon buga ya wuce ta hanyar tsagi.

② Hana ɗayan ɓangaren abubuwan da aka gyara daga faɗuwa a cikin walda mai sake gudana (tsarin walda mai fuska biyu). A cikin tsarin sake walda mai gefe biyu, don hana manyan na'urori da ke gefen da aka siyar daga faɗuwa saboda zafin narkar da mai siyar, ya kamata a yi manne SMT.

③ Hana ƙaura da tsayawa na abubuwan haɗin gwiwa (tsarin walda da sake kwarara, tsari na riga-kafi). An yi amfani da shi a cikin matakai na walƙiya na sake kwarara da matakai na riga-kafi don hana ƙaura da riser yayin hawa.

④ Alamar (kalaman solder, reflow waldi, pre-shafi). Bugu da ƙari, lokacin da aka canza allunan da aka buga da kuma abubuwan da aka gyara a cikin batches, ana amfani da mannen faci don yin alama.

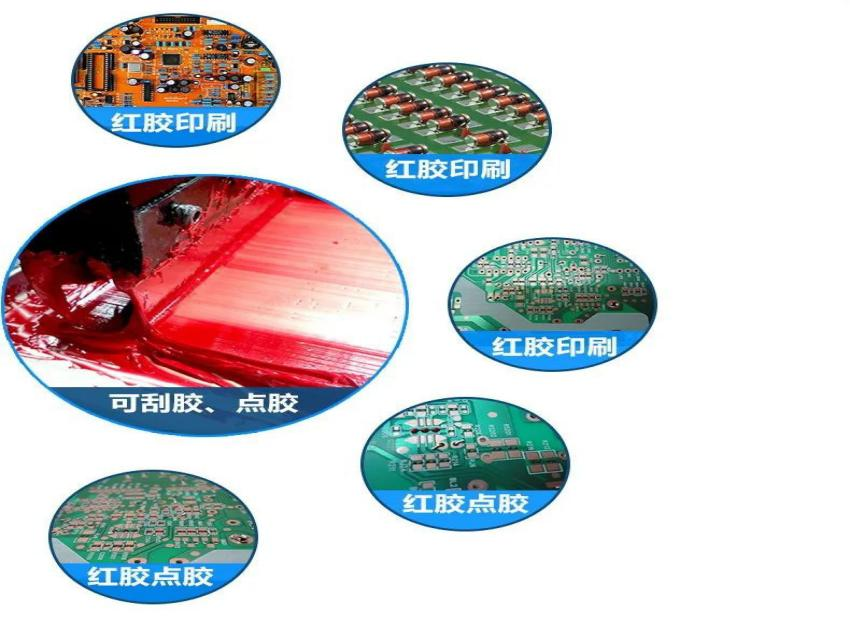

An rarraba manne SMT bisa ga yanayin amfani

a) Nau'in Scraping: Ana yin girman girman ta hanyar bugu da yanayin gogewa na ragar karfe. Wannan hanya ita ce mafi yawan amfani da ita kuma ana iya amfani da ita kai tsaye a kan latsa manna. Ya kamata a ƙayyade ramukan raga na ƙarfe bisa ga nau'in sassa, aikin aikin substrate, kauri da girman da siffar ramukan. Amfaninsa shine babban sauri, babban inganci da ƙarancin farashi.

b) Nau'in rarrabawa: Ana amfani da manne akan allon da aka buga ta hanyar rarraba kayan aiki. Ana buƙatar kayan aikin rarrabawa na musamman, kuma farashin yana da yawa. Rarraba kayan aiki shine amfani da iska mai matsawa, manne ja ta hanyar keɓaɓɓen kai na musamman zuwa ga substrate, girman girman manne, nawa, ta lokacin, diamita bututu mai matsa lamba da sauran sigogi don sarrafawa, injin rarraba yana da aiki mai sassauƙa. Don sassa daban-daban, zamu iya amfani da kawunan rarraba daban-daban, saita sigogi don canzawa, Hakanan zaka iya canza siffar da adadin manne manne, don cimma sakamako, fa'idodin sun dace, sassauƙa da kwanciyar hankali. Rashin hasara yana da sauƙi don samun zanen waya da kumfa. Za mu iya daidaita sigogin aiki, gudu, lokaci, matsa lamba na iska, da zafin jiki don rage waɗannan gazawar.

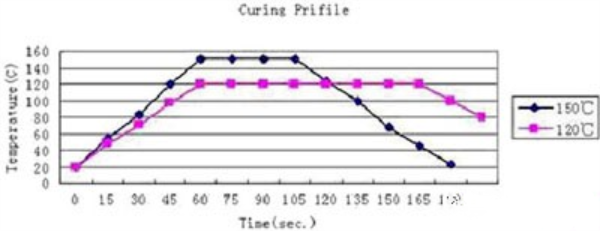

SMT faci na yau da kullun yanayin warkewa

| Maganin zafin jiki | Lokacin warkewa |

| 100 ℃ | Minti 5 |

| 120 ℃ | 150 seconds |

| 150 ℃ | 60 seconds |

Lura:

1, mafi girma da warkewa zafin jiki da kuma tsawon curing lokaci, da karfi da bonding ƙarfi.

2, saboda yawan zafin jiki na facin manne zai canza tare da girman sassan sassan da kuma matsayi mai hawa, muna bada shawara don nemo yanayin hardening mafi dacewa.

Adana faci na SMT

Ana iya adana shi na tsawon kwanaki 7 a dakin da zafin jiki, fiye da watanni 6 a ƙasa da 5 ° C, kuma fiye da kwanaki 30 a 5 ~ 25 ° C.

Gudanar da adhesive SMT

Saboda SMT patch ja manne yana shafar zafin jiki tare da danko, ruwa, jika da sauran halaye, don haka SMT facin ja manne dole ne ya sami wasu sharuɗɗan amfani da daidaitaccen gudanarwa.

1) Red manne yakamata ya sami takamaiman lambar kwarara, gwargwadon adadin ciyarwa, kwanan wata, rubuta zuwa lamba.

2) Ya kamata a adana jan manne a cikin firiji a 2 ~ 8 ° C don hana halayen halayen lalacewa saboda canjin yanayin zafi.

3) Ana buƙatar manne ja don dumama a cikin zafin jiki na tsawon sa'o'i 4, a cikin tsari na farko-in-farko amfani.

4) Domin aikin rarrabawa, sai a daskare jan man da ke cikin bututun, sannan a mayar da jan man da ba a yi amfani da shi ba a cikin firij domin ajiya, sannan ba za a iya hada tsohon gam da sabon gam ba.

5) Don daidai cika fom ɗin rikodin zazzabi na dawowa, dawo da mutum zafin jiki da dawo da lokacin zafin jiki, mai amfani yana buƙatar tabbatar da cikar yanayin zafin dawowa kafin amfani. Gabaɗaya, ba za a iya amfani da manne ja da baya ba.

Halayen tsari na mannen facin SMT

Ƙarfin haɗin haɗi: SMT manne dole ne ya sami ƙarfin haɗin gwiwa mai ƙarfi, bayan an taurare, ko da a zafin jiki na narkewa na solder baya kwasfa.

Rufe digo: A halin yanzu, hanyar rarraba allunan da aka buga galibi shafi ɗigo ne, don haka ana buƙatar manne don samun abubuwa masu zuwa:

① Daidaita zuwa matakai daban-daban na hawa

Sauƙi don saita wadatar kowane bangare

③ Sauƙi don daidaitawa don maye gurbin nau'ikan abubuwan

④ Adadin suturar ɗigo mai tsayi

Daidaita da na'ura mai sauri: mannen facin da aka yi amfani da shi a yanzu dole ne ya hadu da babban sauri na murfin tabo da na'ura mai sauri mai sauri, musamman, wato, murfin tabo mai sauri ba tare da zanen waya ba, kuma wannan shine, hawan mai sauri, allon bugawa a cikin tsarin watsawa, manne don tabbatar da cewa abubuwan da aka gyara ba su motsa ba.

Waya zane, rugujewa: da zarar faci manne ga kushin, da aka gyara ba zai iya cimma lantarki dangane da buga jirgin, don haka faci manne dole ne babu waya zane a lokacin shafi, babu rushewa bayan shafi, don haka kamar yadda ba ya gurbata da kushin.

Maganin ƙananan zafin jiki: Lokacin da ake warkewa, abubuwan da ke jure zafin zafi waɗanda aka haɗa tare da waldawar igiyar igiyar ruwa yakamata su wuce ta cikin tanderun walda, don haka yanayin taurare dole ne ya dace da ƙarancin zafin jiki da ɗan gajeren lokaci.

Gyaran kai: A cikin aikin walda da riga-kafi, ana gyara mannen patch ɗin kafin a narke, don haka zai hana abin da ke ciki nutsewa cikin solder da daidaitawa. Dangane da wannan, masana'antun sun haɓaka faci mai daidaitawa.

SMT matsaloli gama gari, lahani da bincike

rashin amincewa

Ƙarfin ƙarfin da ake buƙata na 0603 capacitor shine 1.0KG, juriya shine 1.5KG, ƙarfin ƙarfin ƙarfin 0805 shine 1.5KG, juriya shine 2.0KG, wanda ba zai iya kaiwa ga abin da ke sama ba, yana nuna cewa ƙarfin bai isa ba.

Yawanci yana haifar da dalilai masu zuwa:

1, yawan manne bai isa ba.

2, Colloid baya warkewa 100%.

3, PCB allon ko abubuwan da aka gurbata.

4, Colloid ita kanta ba ta da ƙarfi, ba ta da ƙarfi.

Thixotropic rashin zaman lafiya

Manne sirinji na 30ml yana buƙatar buga dubun duban sau ta hanyar iska don amfani da shi, don haka ana buƙatar facin da kansa don samun kyakkyawan thixotropy, in ba haka ba zai haifar da rashin kwanciyar hankali na manne, manne kaɗan, wanda zai haifar da ƙarancin ƙarfi, yana haifar da abubuwan da aka gyara yayin siyarwar igiyar ruwa, akasin haka, adadin manne yana da sauƙi sosai, musamman don haɗawa da ƙananan abubuwan haɗin gwiwa.

Rashin isassun manne ko wurin zubewa

Dalilai da Magani:

1, ba a tsaftace allon bugawa akai-akai, yakamata a tsaftace shi da ethanol kowane awa 8.

2, Colloid yana da najasa.

3, buɗe allo na raga ba shi da ma'ana kuma ƙarami ne ko matsi na rarraba ya yi ƙanƙanta, ƙirar ƙarancin manne.

4, akwai kumfa a cikin colloid.

5. Idan an katange kan mai rarrabawa, ya kamata a tsaftace bututun da aka watsa nan da nan.

6, preheating zafin jiki na rarraba kai bai isa ba, zafin jiki na rarraba kai ya kamata a saita a 38 ℃.

zanen waya

Abin da ake kira zanen waya shi ne lamarin da cewa mannen facin ba ya karyewa lokacin da ake rarrabawa, kuma ana haɗa mannen facin ta hanyar filamentous ta hanyar da ke ba da kai. Akwai ƙarin wayoyi, kuma an rufe manne facin akan kushin da aka buga, wanda zai haifar da rashin walda. Musamman lokacin da girman ya fi girma, wannan al'amari yana iya faruwa lokacin da bakin shafi. Zane na facin manne ya fi shafa shi ta hanyar kayan zane na babban bangaren guduronsa da saitin yanayin shafi.

1, ƙara yawan bugun jini, rage saurin motsi, amma zai rage bugun bugun ku.

2, mafi ƙarancin danko, babban thixotropy na kayan, ƙarami da hali don zana, don haka gwada zaɓar irin wannan mannen faci.

3, yawan zafin jiki na ma'aunin zafi da sanyio ya dan kadan, an tilasta masa daidaitawa zuwa ƙananan danko, babban manne thixotropic patch, sannan kuma la'akari da lokacin ajiya na manne faci da matsa lamba na kai mai rarrabawa.

caving

Rashin ruwa na facin zai haifar da rushewa. Matsalar gama gari na rushewa ita ce sanya tsayi da yawa bayan murfin tabo zai haifar da rushewa. Idan an shimfiɗa mannen faci zuwa kushin da'irar da aka buga, zai haifar da rashin walƙiya. Kuma rugujewar mannen facin ga waɗannan abubuwan da ke da manyan fil ɗin, baya taɓa babban jikin ɓangaren, wanda zai haifar da ƙarancin mannewa, don haka rugujewar mannewar facin da ke da sauƙin rugujewa yana da wahalar hangowa, don haka saitin farko na adadin ɗigon sa shima yana da wahala. Dangane da wannan, dole ne mu zaɓi waɗanda ba su da sauƙin rugujewa, wato, facin da ke da tsayin daka a cikin maganin girgiza. Don rugujewar lalacewa ta hanyar sanya tsayi da yawa bayan murfin tabo, za mu iya amfani da ɗan gajeren lokaci bayan murfin tabo don kammala manne facin, warkewa don guje wa.

Matsakaicin sashi

Matsakaicin abubuwan da ba a so wani lamari ne da ba a so wanda ke da sauƙin faruwa a cikin injinan SMT masu sauri, kuma manyan dalilan su ne:

1, shi ne bugu jirgin high-gudun motsi na XY shugabanci lalacewa ta hanyar biya diyya, da faci m shafi yankin na kananan aka gyara yiwuwa ga wannan sabon abu, dalilin shi ne cewa adhesion ba a lalacewa ta hanyar.

2, yawan manne a karkashin abubuwan da aka gyara ba daidai ba ne (kamar: maki biyu na manne a karkashin IC, manne guda daya babba ne kuma manne guda daya karami ne), karfin gam din yana rashin daidaito idan an zafi kuma ya warke, kuma karshen tare da ƙarancin manne yana da sauƙin kashewa.

Sama da igiyar ruwa sayar da sassa

Dalilan suna da sarkakiya:

1. Ƙarfin mannewa na facin bai isa ba.

2. An yi tasiri kafin sayar da igiyar ruwa.

3. Akwai sauran ragowar akan wasu sassa.

4, Colloid baya jurewa tasirin zafi mai girma

Faci manne mix

Daban-daban masana'antun na faci manne a cikin sinadaran abun da ke ciki yana da babban bambanci, gauraye amfani ne mai sauki don samar da mai yawa mara kyau: 1, curing wahala; 2, gudun ba da sanda na m bai isa ba; 3, sama da igiyar ruwa soldering kashe tsanani.

Magani shine: tsaftace allon raga, gogewa, rarrabawa da sauran sassa masu sauƙin haifar da haɗuwa, da guje wa haɗa nau'ikan nau'ikan manne daban-daban.