Cikakken tsarin samar da PCBA (gami da duk tsarin DIP), shigo ku gani!

"Tsarin Siyar da Wave"

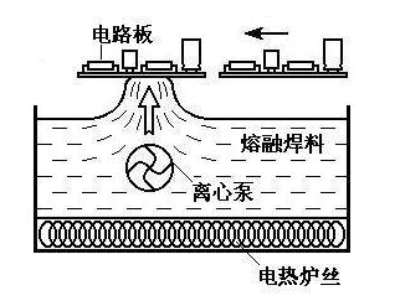

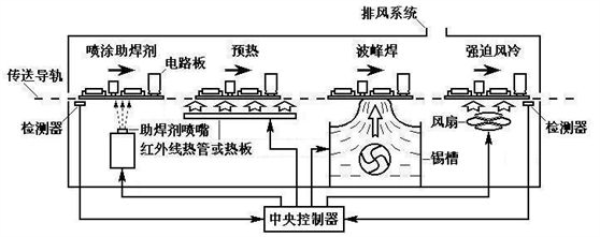

Wave soldering gabaɗaya tsari ne na walda don na'urorin toshewa. Yana da wani tsari a cikin abin da narkakken ruwa solder, tare da taimakon famfo, Forms wani takamaiman siffar solder kalaman a kan ruwa surface na solder tank, da kuma PCB na saka bangaren ya ratsa ta cikin solder kalaman ganiya a wani takamaiman kusurwa da wani zurfin nutsewa a kan watsa sarkar don cimma solder hadin gwiwa waldi, kamar yadda aka nuna a cikin adadi a kasa.

Gudun tsarin gabaɗaya shine kamar haka: shigar da na'ura - lodin PCB --sayar da igiyar ruwa --Cukar da PCB --DIP pin trimming -- tsaftacewa, kamar yadda aka nuna a hoton da ke ƙasa.

1.THC fasahar shigarwa

1. Ƙirƙirar fil ɗin sashi

Na'urorin DIP suna buƙatar a tsara su kafin sakawa

(1) Siffar abubuwan da aka sarrafa ta hannu: Za a iya siffata fil ɗin da aka lanƙwasa tare da tweezers ko ƙaramar screwdriver, kamar yadda aka nuna a hoton da ke ƙasa.

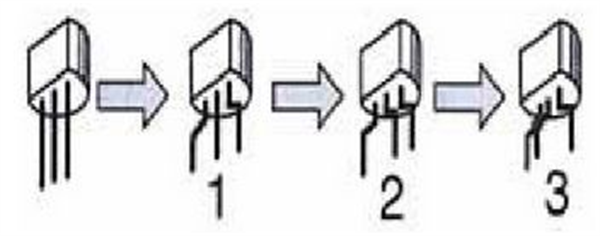

(2) Na'urar sarrafa na'ura na tsara abubuwan da aka gyara: an kammala aikin na'ura na kayan aikin da na'ura na musamman, tsarin aikinsa shine cewa mai ba da abinci yana amfani da ciyarwar vibration don ciyar da kayan abinci, (kamar transistor plug-in) tare da mai rarraba don gano inda transistor, mataki na farko shine lanƙwasa fil a bangarorin biyu na hagu da dama; Mataki na biyu shine lanƙwasa fil ɗin tsakiya baya ko gaba don samarwa. Kamar yadda aka nuna a hoto mai zuwa.

2. Saka abubuwa

Ta hanyar fasahar shigar rami ta kasu kashi kashi na hannu da shigar da kayan aikin injin atomatik

(1) Shigarwa da waldawa da hannu ya kamata a fara shigar da abubuwan da ake buƙatar gyarawa ta hanyar injiniya, kamar injin sanyaya, bracket, clip, da sauransu, na na'urar wutar lantarki, sannan a saka abubuwan da ake buƙatar waldawa da gyarawa. Kar a taɓa fil ɗin abubuwan da ke kan farantin bugawa kai tsaye lokacin sakawa.

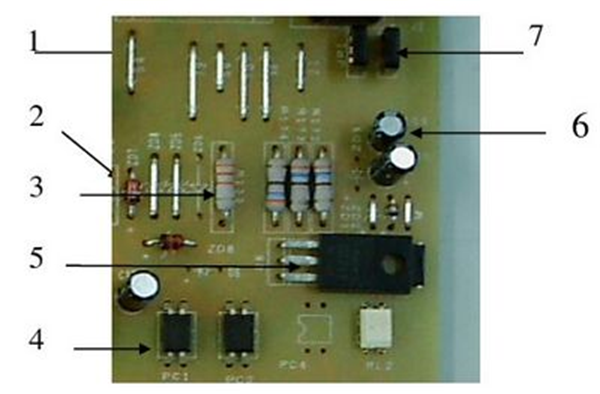

(2) Filogin injina ta atomatik (wanda ake magana da AI) shine mafi haɓaka fasahar samarwa mai sarrafa kansa a cikin shigar da samfuran lantarki na zamani. Shigar da kayan aikin injiniya na atomatik ya kamata a fara shigar da waɗannan abubuwan da ke da ƙananan tsayi, sannan shigar da waɗannan abubuwan da ke da tsayi mafi girma. Yakamata a saka mahimman abubuwan mahimmanci a cikin shigarwa na ƙarshe. Shigar da tarkacen zafi mai zafi, sashi, clip, da dai sauransu ya kamata ya kasance kusa da tsarin walda. Ana nuna jerin abubuwan haɗin PCB a cikin adadi mai zuwa.

3. Wave soldering

(1) Ƙa'idar aiki na sayar da igiyar ruwa

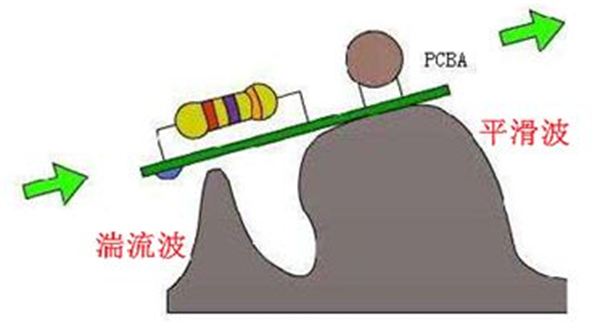

Wave soldering wani nau'i ne na fasaha da ke samar da takamaiman nau'i na igiyar solder akan saman narkakken ruwa mai solder ta hanyar famfo matsewa, kuma yana samar da wurin siyar a cikin yankin waldawar fil lokacin da ɓangaren haɗakarwa tare da sashin ya wuce ta hanyar igiyar solder a madaidaicin kusurwa. An fara ɗora kayan aikin a cikin na'urar preheating na walda yayin aiwatar da watsawa ta hanyar isar da sarkar (haɓaka yanayin zafin jiki da zafin jiki da za a samu har yanzu ana sarrafa shi ta hanyar ƙayyadaddun yanayin zafin jiki). A cikin walƙiya na ainihi, yawanci ya zama dole don sarrafa zafin zafin jiki na zafin jiki, don haka na'urori da yawa sun ƙara na'urorin gano zafin jiki daidai (kamar masu gano infrared). Bayan preheating, taron yana shiga cikin ramin gubar don walda. Tankin gwangwani yana dauke da narkakkar sodar ruwa, kuma bututun da ke kasan tankin karfen yana fesa wata kafaffen igiyar igiyar igiyar igiyar ruwa ta narkakkar, ta yadda idan saman walda na bangaren ya ratsa ta cikin igiyar ruwa, sai ya yi zafi da igiyar solder, sannan igiyar solder ita ma tana dankar wurin walda kuma ta fadada ta cika, a karshe ta cimma aikin walda. An nuna ka'idar aikin sa a cikin hoton da ke ƙasa.

Siyar da igiyar igiyar ruwa tana amfani da ƙa'idar canja wurin zafi don dumama wurin walda. Narkakken solder igiyar ruwa yana aiki ne azaman tushen zafi, a gefe guda kuma yana gudana don wanke yankin waldawar fil, a gefe guda kuma yana taka rawar zafi, kuma wurin waldawar fil yana dumama ƙarƙashin wannan aikin. Domin tabbatar da cewa wurin waldawar ya yi zafi, igiyar walda ta kan kasance tana da wani faxi, ta yadda idan fuskar walda ta ratsa ta igiyar za a samu isassun dumama, jika, da dai sauransu. A cikin siyar da igiyar igiyar ruwa na gargajiya, ana amfani da igiyar ruwa guda ɗaya gabaɗaya, kuma igiyar tana da ɗan lebur. Tare da yin amfani da mai siyar da gubar, a halin yanzu an karbe shi ta hanyar igiyar ruwa biyu. Kamar yadda aka nuna a hoto mai zuwa.

Fin ɗin ɓangaren yana ba da hanya don mai siyar don tsomawa cikin ƙarfe da aka yi ta cikin rami a cikin ƙasa mai ƙarfi. Lokacin da fil ɗin ya taɓa igiyar siyarwar, mai siyar da ruwa ya hau bangon fil da rami ta hanyar tashin hankali na saman. Ayyukan capillary na ƙarfe ta hanyar ramuka yana inganta hawan solder. Bayan mai siyar ya isa kushin PcB, ya bazu a ƙarƙashin aikin tashin hankali na kushin. Solder mai tasowa yana zubar da iskar gas da iska daga ramin, don haka ya cika ramin da samar da hadin gwiwar solder bayan sanyaya.

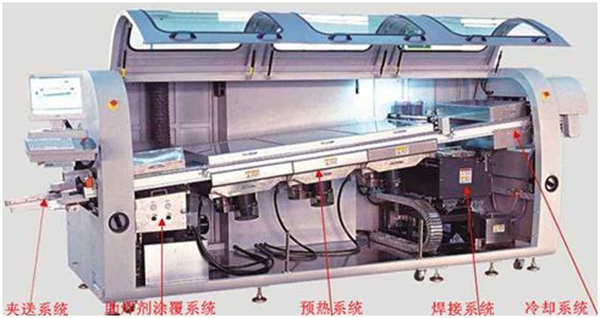

(2) Babban abubuwan da ke cikin injin walda igiyar ruwa

Na'urar walda igiyar igiyar ruwa ta ƙunshi bel mai ɗaukar nauyi, injin dumama, tankin kwano, famfo, da na'urar yin kumfa (ko fesa). An rarraba shi zuwa yankin ƙara juyi, yankin preheating, yankin walda da yankin sanyaya, kamar yadda aka nuna a cikin adadi mai zuwa.

3. Babban bambance-bambance tsakanin kalaman soldering da reflow waldi

Babban bambanci tsakanin igiyar ruwa soldering da reflow waldi shi ne cewa dumama tushen da solder wadata hanya a cikin waldi ne daban-daban. A cikin siyar da igiyar ruwa, ana yin zafi da narkakken solder a cikin tanki, kuma igiyar solder da famfo ke samarwa yana taka rawar dual na tushen zafi da samar da solder. Ruwan narkakkar solder yana dumama ta ramuka, pads, da fitattun abubuwan PCB, yayin da kuma ke samar da solder ɗin da ake buƙata don samar da haɗin gwiwa. A reflow soldering, solder (solder manna) an riga an kasafta shi zuwa yankin walda na PCB, da kuma rawar da zafi tushen a lokacin reflow shi ne ya sake narke solder.

(1) 3 Gabatarwa zuwa tsarin siyar da igiyar igiyar ruwa

Wave soldering kayan aiki da aka ƙirƙira fiye da shekaru 50, kuma yana da abũbuwan amfãni daga high samar yadda ya dace da kuma babban fitarwa a cikin masana'antu na ta-rami aka gyara da kewaye allon, don haka shi ne sau daya mafi muhimmanci waldi kayan aiki a atomatik taro samar da lantarki kayayyakin. Koyaya, akwai wasu iyakoki a aikace-aikacen sa: (1) sigogin walda sun bambanta.

Ganyayyaki daban-daban akan allon kewayawa ɗaya na iya buƙatar sigogin walda daban-daban saboda halayensu daban-daban (kamar ƙarfin zafi, tazarar fil, buƙatun shigar kwano, da sauransu). Duk da haka, da hali na kalaman soldering ne don kammala waldi na duk solder gidajen abinci a kan dukan kewaye hukumar karkashin wannan sa sigogi, don haka daban-daban solder gidajen abinci bukatar "zaure" juna, wanda ya sa kalaman soldering mafi wuya ga cika da waldi bukatun na high quality-circuit allon;

(2) Yawan farashin aiki.

A cikin aikace-aikacen da ake yi na sayar da igiyar igiyar ruwa ta gargajiya, feshin farantin gabaɗaya da samar da tin slag yana kawo tsadar aiki. Musamman a lokacin walda ba tare da gubar ba, saboda farashin da ba shi da gubar ya ninka fiye da sau 3, karuwar farashin aiki da tin slag ke haifarwa yana da matukar mamaki. Bugu da ƙari, mai siyar da ba ta da gubar ya ci gaba da narkar da tagulla a kan kushin, kuma abun da ke cikin silinda a cikin kwandon kwandon zai canza a kan lokaci, wanda ke buƙatar ƙarawa na yau da kullum na tin mai tsabta da azurfa mai tsada don warwarewa;

(3) Matsalar kulawa da kulawa.

Saurin juzu'i a cikin samarwa zai kasance a cikin tsarin watsawa na siyar da igiyar ruwa, kuma tin slag ɗin da aka samar yana buƙatar cirewa akai-akai, wanda ke kawo ƙarin kayan aiki masu rikitarwa da aikin kulawa ga mai amfani; Don irin waɗannan dalilai, zaɓin igiyar igiyar ruwa ya zama.

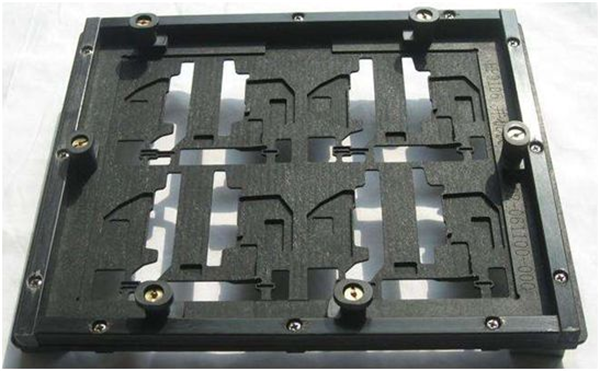

Har ila yau, abin da ake kira PCBA selective wave soldering yana amfani da asalin murhun murhu, amma bambancin shi ne cewa ana buƙatar sanya allon a cikin ma'ajiyar tanderun, abin da muke yawan faɗi game da tanderun, kamar yadda aka nuna a hoton da ke ƙasa.

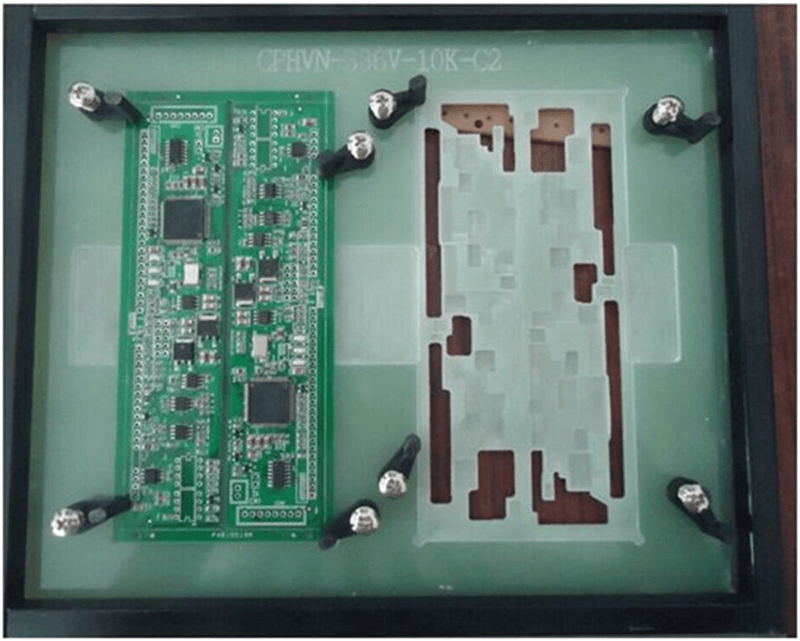

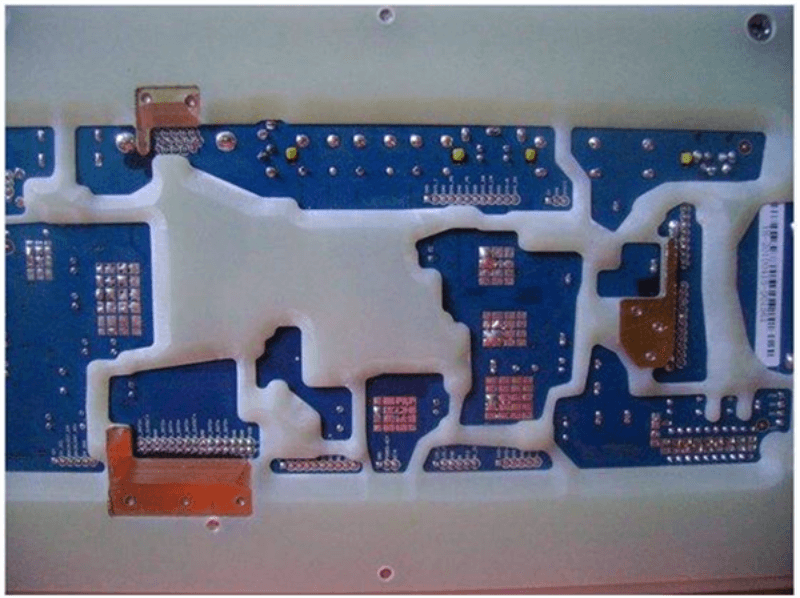

Sassan da ke buƙatar siyar da igiyar igiyar ruwa ana fallasa su zuwa tin, sauran sassan kuma ana kiyaye su da abin hawa, kamar yadda aka nuna a ƙasa. Wannan kadan ne kamar sanya abin hawa na rayuwa a cikin tafkin, wurin da buoy din rai ya lullube ba zai samu ruwa ba, a maye gurbinsa da murhu na kwano, wurin da abin hawa ya lullube shi a dabi’ance ba zai samu tin ba, kuma ba za a sami matsala ta sake narkewa ko faduwa ba.

"Ta hanyar reflow reflowing Processing"

Walda reflow ta hanyar-rami tsari ne na waldawa mai sake gudana don saka abubuwan da aka gyara, wanda galibi ana amfani da shi wajen kera faranti na taro mai ɗauke da ƴan filogi. Jigon fasaha shine hanyar aikace-aikacen na manna solder.

1. Gabatarwar tsari

Bisa ga aikace-aikace Hanyar solder manna, ta rami reflow waldi za a iya raba uku iri: bututu bugu ta rami reflow walda tsari, solder manna bugu ta rami reflow walda tsari da gyaggyarawa tin takardar ta hanyar rami reflow walda tsari.

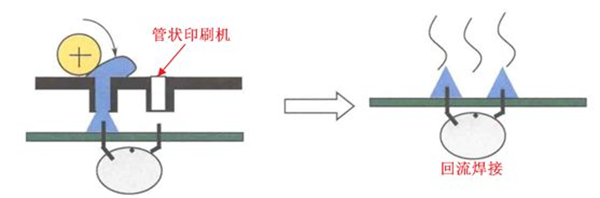

1) Tubular bugu ta hanyar rami reflow waldi tsari

Buga Tubular ta hanyar tsarin waldawa na reflow shine farkon aikace-aikacen ta hanyar abubuwan da aka gyara na ramuka reflow tsarin walda, wanda akafi amfani dashi wajen kera na'urar gyara talabijin mai launi. Jigon tsari shine latsa tubular manna mai siyarwa, ana nuna tsarin a cikin hoton da ke ƙasa.

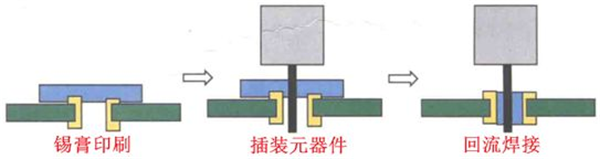

2) Solder manna bugu ta rami reflow waldi tsari

Solder manna bugu ta hanyar rami reflow waldi tsari ne a halin yanzu mafi yadu amfani ta hanyar rami reflow waldi tsari, yafi amfani ga gauraye PCBA dauke da wani karamin adadin toshe-ins, da tsari ne cikakken jituwa tare da al'ada reflow waldi tsari, babu musamman tsari kayan aiki da ake bukata, kawai abin da ake bukata shi ne cewa welded toshe-in aka gyara dole ne dace da ta hanyar rami reflow waldi aka nuna a cikin adadi, da tsari.

3) Molding tin takardar ta hanyar rami reflow waldi tsari

Molded tin sheet ta hanyar rami reflow waldi tsari ne yafi amfani ga Multi-pin haši, solder ba solder manna amma gyare-gyaren takardar tin, gabaɗaya ta mai haɗawa kai tsaye ƙara da cewa taro za a iya mai tsanani kawai.

Ta hanyar buƙatun ƙira reflow

1.PCB zane bukatun

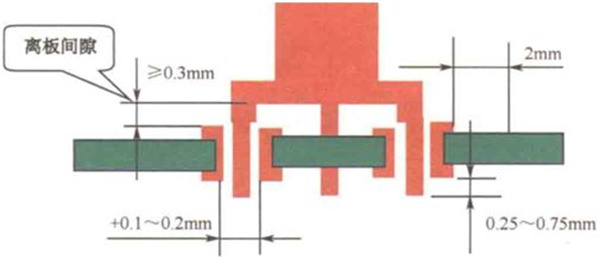

(1) Ya dace da kauri na PCB ƙasa da ko daidai da allon 1.6mm.

(2) Mafi ƙarancin faɗin kushin shine 0.25mm, kuma narkakken solder ɗin ana “jawo” sau ɗaya, kuma ba a samar da kwano ba.

(3) Matsalolin kashe allo (Tsaya-kashe) ya kamata ya fi 0.3mm

(4) Tsawon da ya dace na gubar da ke fita daga cikin kushin shine 0.25 ~ 0.75mm.

(5) Matsakaicin tazara tsakanin kyawawan abubuwan tazara kamar 0603 da kushin shine 2mm.

(6) Matsakaicin buɗaɗɗen ragar ƙarfe na iya faɗaɗa ta 1.5mm.

(7) Aperture ne gubar diamita da 0.1 ~ 0.2mm. Kamar yadda aka nuna a hoto mai zuwa.

"Buƙatun buɗe taga karfe raga"

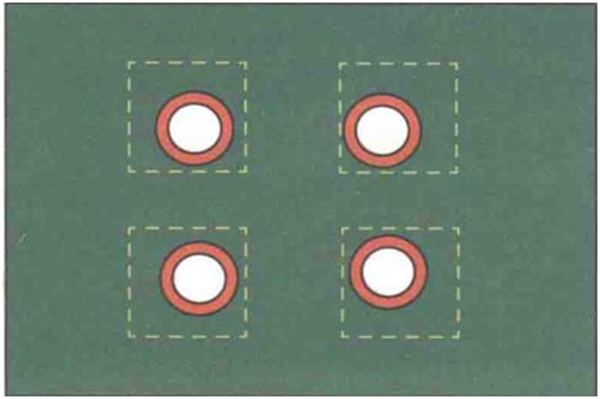

Gabaɗaya, don cimma nasarar cika rami na 50%, dole ne a faɗaɗa taga tagar ƙarfe na ƙarfe, ƙayyadaddun adadin fadada waje ya kamata a ƙayyade bisa ga kauri na PCB, kauri na ragar ƙarfe, rata tsakanin rami da gubar da sauran dalilai.

Gabaɗaya, idan dai faɗaɗa bai wuce 2mm ba, za a ja da manna solder a baya kuma a cika shi cikin rami. Ya kamata a lura cewa fadada waje ba za a iya matsawa ta hanyar kunshin kayan aikin ba, ko kuma dole ne a guje wa kunshin kayan aikin, kuma a samar da kwano a gefe guda, kamar yadda aka nuna a cikin adadi mai zuwa.

"Gabatarwa ga Tsarin Taro na al'ada na PCBA"

1) Hawan gefe guda ɗaya

Ana nuna kwararar tsari a cikin hoton da ke ƙasa

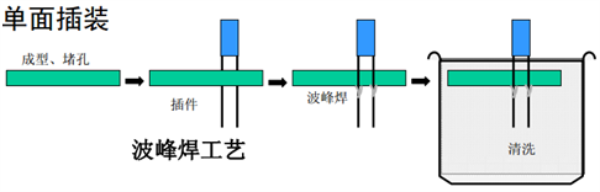

2) Saka gefe guda ɗaya

Ana nuna kwararar tsari a cikin hoto na 5 a ƙasa

Samar da fitilun na'urar a cikin siyar da igiyar ruwa yana ɗaya daga cikin mafi ƙarancin ingantaccen ɓangarorin samarwa, wanda daidai yake yana kawo haɗarin lalacewar electrostatic kuma yana tsawaita lokacin isarwa, kuma yana haɓaka damar kuskure.

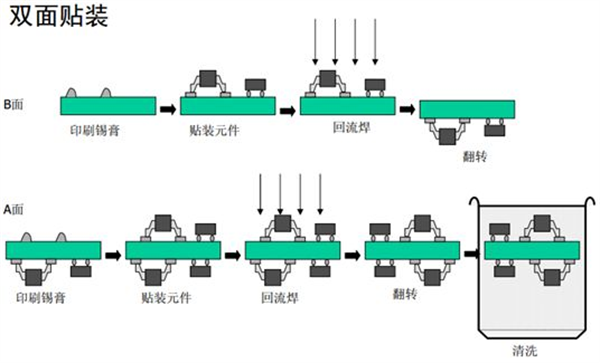

3) Hawan gefe biyu

Ana nuna kwararar tsari a cikin hoton da ke ƙasa

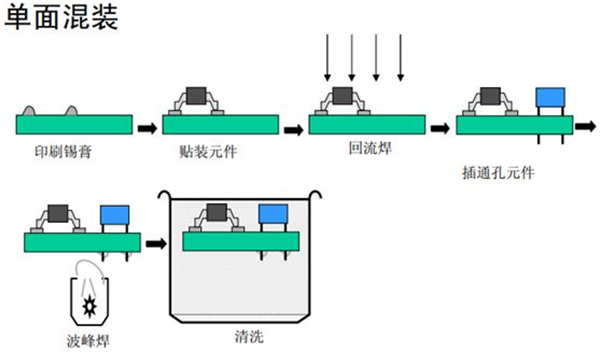

4) Gefe daya gauraye

Ana nuna kwararar tsari a cikin hoton da ke ƙasa

Idan akwai ƴan abubuwan haɗin ramuka, za'a iya amfani da walda mai sake gudana da walƙiya ta hannu.

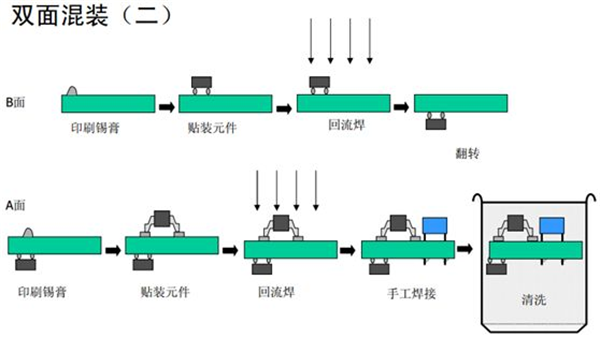

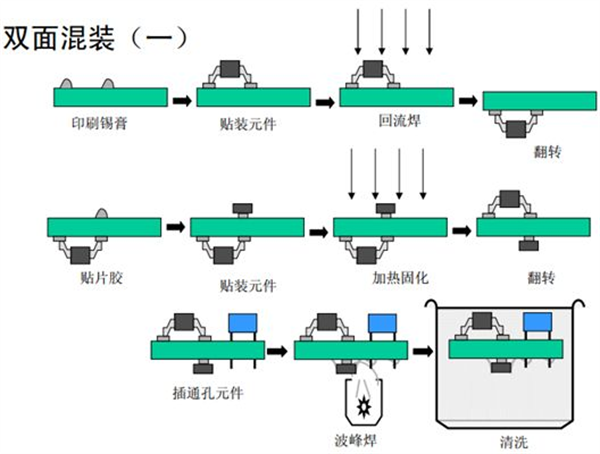

5) Hadin fuska biyu

Ana nuna kwararar tsari a cikin hoton da ke ƙasa

Idan akwai ƙarin na'urorin SMD masu gefe biyu da ƴan abubuwan TTHT, na'urorin plug-in na iya zama sake kwarara ko walda ta hannu. Ana nuna ginshiƙi mai gudana a ƙasa.